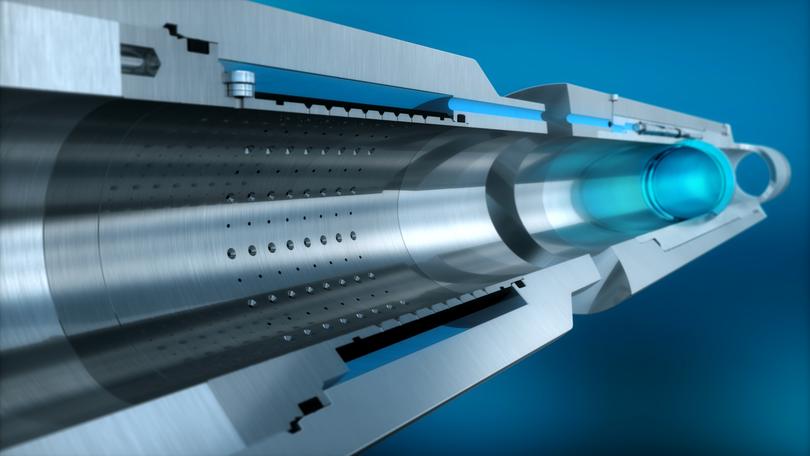

The TDP-3 HPHT is based on TCO’s original TDP barrier plugs, with the addition of improved installation and remote cycling capabilities. The product incorporates TCO’s patented laminated glass material, built into an ISO 14310 V0 certified barrier plug package. This provides a total seal against all fluids under extreme conditions, even in situations with high differential pressure across the barrier.

Our patented laminated glass barrier material provides a secure, non-corrodible seal under high temperatures and axial loads, and is capable of withstanding extreme levels of differential pressure from both sides. The laminated glass disintegrates into small particles (silica) upon removal.

The TDP-3 HPHT is designed to be installed and runs as an integrated part of the completion string or liner. This increases the efficiency of the installation process and provides a large bore access when the plug is opened. The TDP-3 HPHT uses rubber diaphragms to separate wellbore fluids from the clean fluid, as well as keep the cycling mechanism debris free.

In addition to the built-in remote opening mechanism, a variety of removal options are available as a contingency. Full ID is always guaranteed after opening.

The TDP-3 HPHT is supplied with a 4.5 metre debris extension as standard for use in wells with expected debris issues.

Features and Benefits

- Large bore access

- Safer Operations

- No external personnel required

- ISO 14310 V0 certified

- Debris tolerant

- In-built redundant cycling mechanism

- Lower Costs

- Intervention-free installation

- Remote removal capability

- Reduce rig time

- Easy removal compared to deepset/horizontal wireline plugs

- HPHT

- Laminated glass

- Debris extension

- Integrated installation

Applications

- Completion barrier plug

- Isolate lower completion while installing upper completion

- Reduce/eliminate need of intervention operations

- Packer setting device

- Fluid loss control device

- HPHT wells