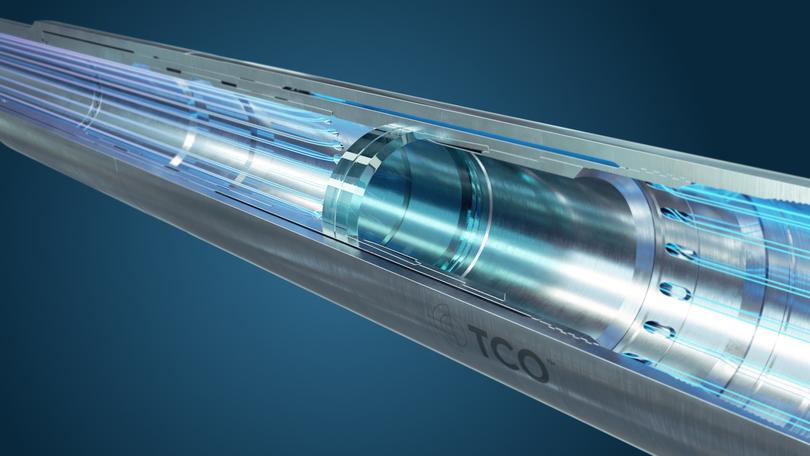

The design of the DSBP is a combination of the learnings made from the traditional TCO glass plugs and the development of the Disappearing Tubing Hanger Plug (DTHP). Running in hole, the bypass is open, allowing for auto-filling of tubing and later displacement of heavy well fluids to lighter completion fluids. When closed, the DSBP can be suspended for a long time as a full V0 qualified barrier. After removal of barrier, production or injection can start through the large bore ID.

The DSBP will be operated remotely in all aspects, closing the bypass sleeve to ensure the barrier in place with an electronic cycling device, and later remotely cycled open by use of the self-calibrated Balanced Counter once communication is needed to the reservoir.

An E-trigger device is used to close the bypass sleeve, and the data to operate the electronic cycling device will be set up based on well data supplied from the operator. It can be activated based on pressure cycles or by using a pre-set activated timer. There are multiple choices of cycling available, from only an activation cycle to many cycles to increase the operating window of the device. TCO has through the years had great experience with the use of electronic devices for remote operation of glass plugs.

The TCO debris extension along with balanced counter is used to remote cycle open the glass barrier, which is broken mechanically. The balanced counter increases is a very versatile system, as it is hydrostatically balanced and does not have to be set up for each well as the hydrostatic pressure will self-calibrate. Once the plug is ready to be cycled, a pressure differential of 2400psi (165bar) must be used to cycle the plug open.

The DSBP uses the same barrier technology as the well proven TDP-NonEx. In addition to the built-in remote opening mechanism, a variety of removal options are available as a contingency. Full ID is always guaranteed after opening.

Features

- Remote cycled E-trigger to close bypass

- Balanced Counter with debris extension to open barrier

- Full V0 validated barrier

- Erosion tested

- Mechanical glass barrier removal

- Debris extension system

Benefits

- Autofill while running in hole

- Bypass allows for displacement of fluid through plug

- Reduced stress on formation – Less surge and swab

- Ability to bull-head through plug

- Remote activation

- E-trigger offers low cycling pressure which reduces stress on reservoir

- Self-calibrating Balanced Counter adapts to well pressure and enables batch-completion

- Run as integral part of completion string

- No explosives - Easier transport and handling

- Debris tolerant activation systems

- Premium connections according to customer specification

Applications

- Barrier plug for running open-ended completions

- Pressure testing and packer setting device