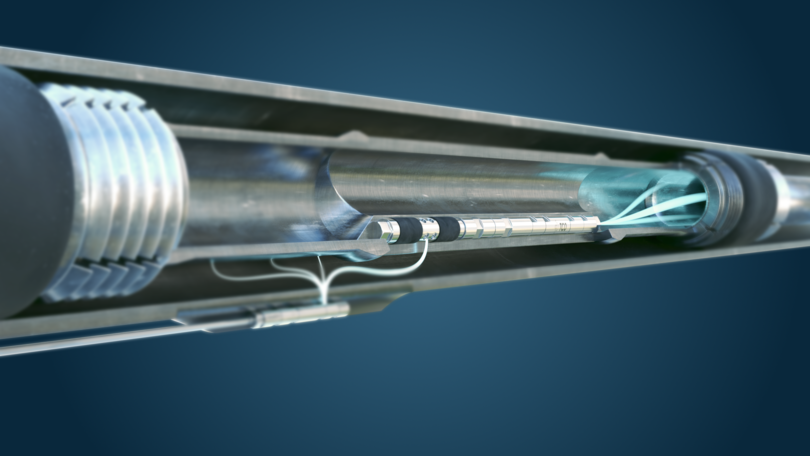

The Straddle Mandrel is designed to be run in a 5 ½” completion where it will allow for straddling and recovering an existing barrier leaking CI mandrel and valve.

It is connected to a 3rd party retrievable straddle packer system to form an annulus to facilitate chemical injection through the existing control line and well completion. The Straddle Mandrel has a side pocket for a Chemical Injection Valve with an upper and lower seal stack.

The valve includes the HN-series forming the core barrier. If back-pressure is needed the FN-series can be added.

Features and Benefits

• Up to 2000 psi back-pressure (FN-series)

• ISO 14310 V0 barrier qualified (HN-series check valves)

Applications

• Seal off leaking valve and continue injection