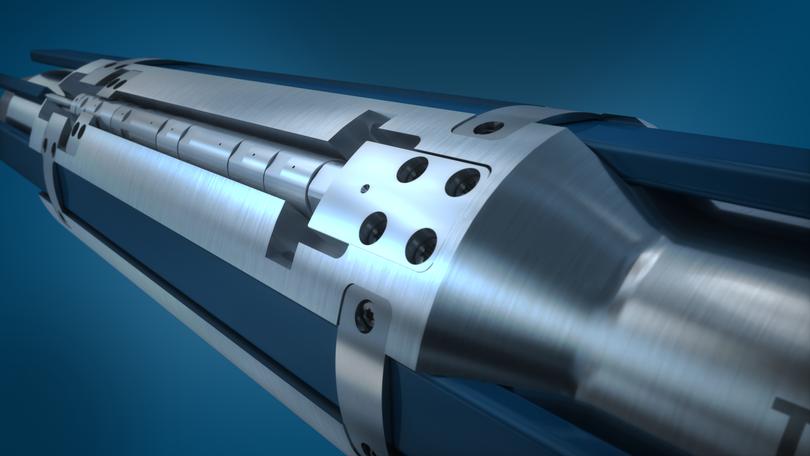

As part of the company's total solution to customers' chemical injection challenges, TCO's Chemical Injection Mandrel (CIM) is designed to meet the requirements of even the most demanding environments.

The TCO Chemical Injection Mandrel is available in a wide range of standardized premium connections and sizes. In addition, the ability to choose the metal from which the mandrel body is constructed ensures compatibility with the well fluid. To ensure a flow path for chemicals, the CIM design includes an Inconel interface block featuring a high alloy construction, metal to metal sealing right through the point of injection into the wellbore. The interface block also offers the benefit of external testing using a test straddle prior to run-in hole. This allows the metal-to-metal sealing between the interface block and the mandrel to be externally pressure tested to validate integrity with the CIV installed.

The Chemical Injection Mandrel is a tubing retrievable system, with a chemical injection valve permanently installed on the mandrel. This is further connected to the surface by a chemical injection line attached to the tubing OD. The system is retrieved by pulling the tubing from the well.

When installed, the injection valve remains independent of the mandrel loading. This ensures that the integrity of sealing surfaces is maintained throughout the entire life of the well.

Features and Benefits

• Metal to metal sealing through the flow path from the valve into the wellbore

• Injection valve is independent of mandrel loading

• All connections externally pressure testable

• Wide range of materials, sizes and premium connections

Applications

• Continuous chemical injection wells

• HPHT