Benefits

-

Transportable via air freight at Class 1.4s

-

Conforms to API RP-67

-

Can be run through heavy mud, paraffin, collapsed tubing and reduced restrictions

-

Can be run 4X faster than conventional jet cutters

-

Must be run decentralized to maximize effectiveness of tool

Technical Data

|

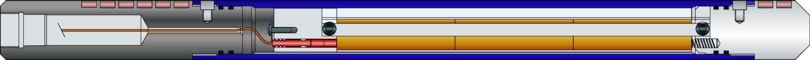

Tool |

1-3/8 IN. |

2 IN. |

||||||

|

Tool Diameter |

1-3/8 IN. |

34.9 MM |

1.375 IN. |

34.9 MM |

2.000 IN. |

50.8 MM |

2.000 IN. |

50.8 MM |

|

Housing Material |

Aluminium |

|||||||

|

Explosive Length |

18, 24 in. |

18, 24, 48 in. |

||||||

|

45.7, 70.0 cm |

45.7, 70.0 cm |

45.7, 70.0, 122.0 cm |

||||||

|

Explosive Load |

600 grain/ft |

900 grain/ft |

1200 grain/ft |

2000 grain/ft |

||||

|

Minimum Running Restriction |

1.775 in. |

45.1 mm |

1.775 in. |

45.1 mm |

2.625 in. |

66.7 mm |

2.625 in. |

66.7 mm |

|

Recommended Tubing |

2.375 to 2.875 in |

2.875 to 4.500 in. |

3.500 to 7.000 in. |

5.500 to 16.000 in. |

||||

|

60.3 to 73.0 mm |

73.0 to 114.3 mm |

88.9 to 177.8 mm |

139.7 to 406.4 mm |

|||||

|

Maximum Pressure |

psi |

MPa |

psi |

MPa |

psi |

MPa |

psi |

MPa |

|

Up to 200°F (93°C) |

14,000 |

96.5 |

14,000 |

96.5 |

11,700 |

80.7 |

11,700 |

80.7 |

|

200°F to 325°F |

13,250 |

91.4 |

13,250 |

91.4 |

11,000 |

75.8 |

11,000 |

75.8 |

|

325°F to 400°F |

11,800 |

81.4 |

11,800 |

81.4 |

9,850 |

67.9 |

9,850 |

67.9 |