A critical design requirement in offshore completions is having multiple barriers to prevent any well control issues. Traditionally, operators have used mechanical or hydraulic ball-type valves that are very complex and have shown inconsistent operational results. This is especially true in wells where debris is prevalent.

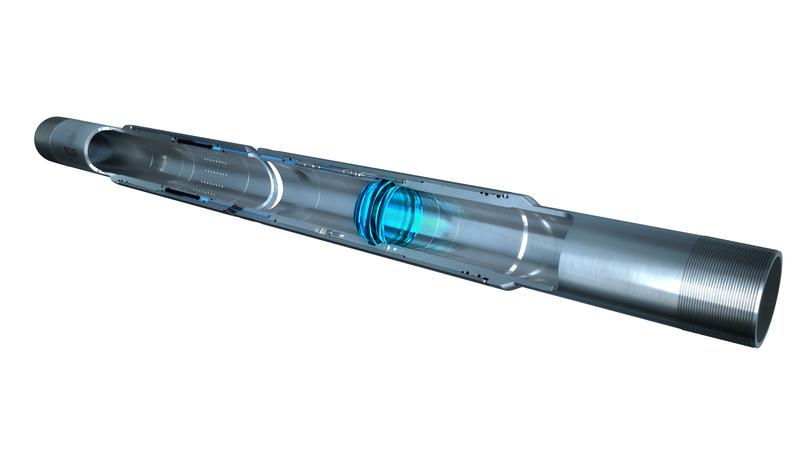

The TDP-3 met the operator’s requirements as a barrier without the unnecessary complications. The valve was RIH below the production packer along with the latching mechanism and seal assembly for the lower completion. Once the production assembly was stabbed into the lower completion, pressure was applied against the TDP-3 to set the packer and isolate the production zones. Prior to production, pressure cycles were applied until the counter reached its predetermined number of cycles at which point the laminated glass barrier was removed and production began.