Product: Completion Barrier Plug, Tubing Disappearing Plug 3 HPHT

Location: Hammerfest, Norway

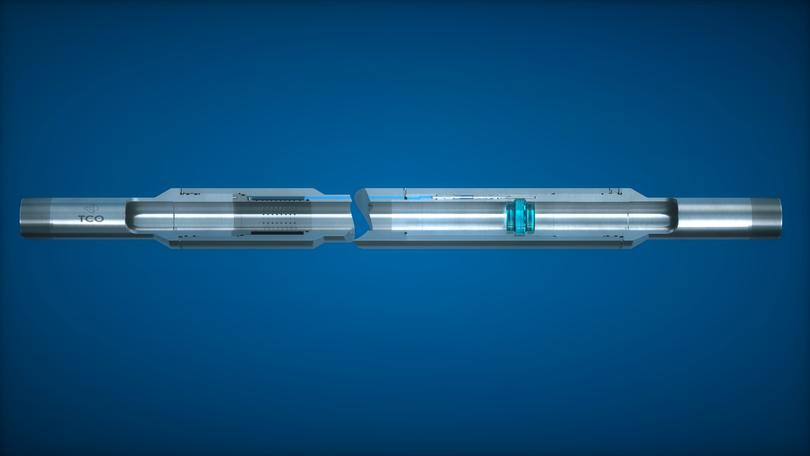

The request came from the Goliat field – an offshore oil field in the Norwegian sector of the Barents Sea located 85 kilometres north-west of Hammerfest. Goliat will be the first oil field to come on stream in the Barents Sea, and is the world’s most northerly offshore development. Two and a half weeks before a completion was due to be run inside a 7” liner, TCO received an order from ENI for a TDP-3 587 x 300 glass plug. Using the glass plug as a barrier, ENI would be able to run perforating guns as part of the completion in a shoot and drop configuration, without exposing the firing heads to pressure when setting the packer and pressure testing the completion. The solution ENI normally uses for longer intervals is to perforate in a separate run (shoot and pull) before running the completion, which is more time consuming. Although the delivery deadline was tight, TCO and ENI maintained close communication in order to ensure that the plug was delivered on time. TCO had a fit for purpose plug on stock, but this required a redress and testing. TCO met these challenges and delivered the plug in Hammerfest within the deadline and without any delays. The plug was cycled open as planned through the application of a pre determined number of pressure cycles, with the laminated glass disintegrating into small particles upon removal.

Successful opening of the plug was also confirmed by DHTP gauge readings. Use of the plug increased the efficiency of the process for ENI and provided large bore access without the use of wireline.

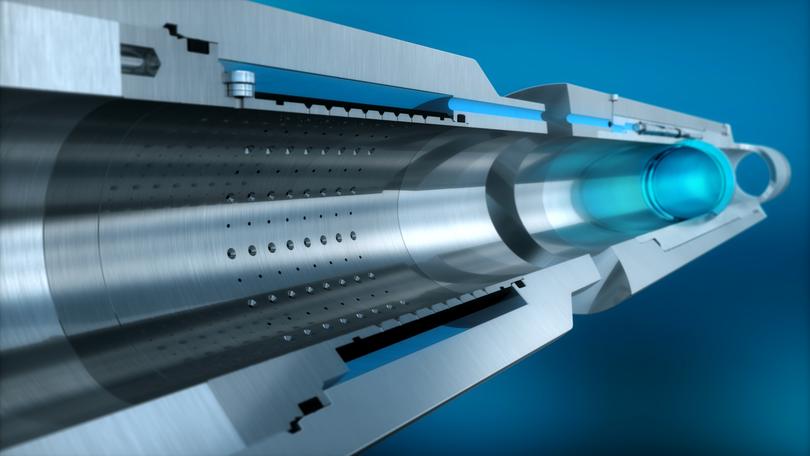

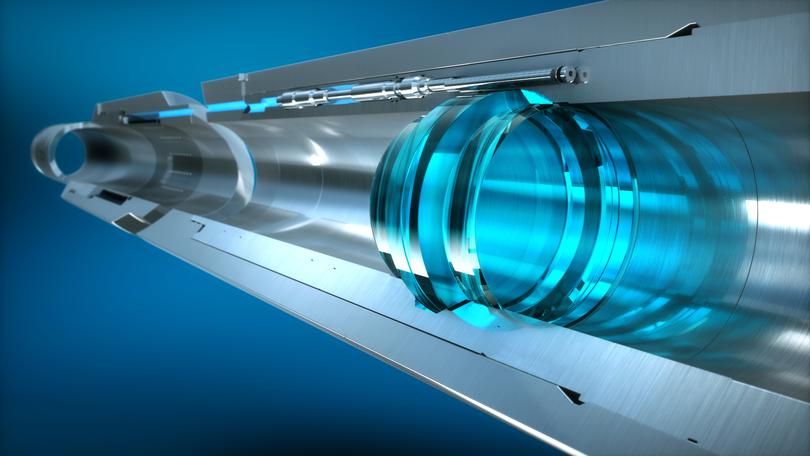

The third generation of the Tubing Disappearing Plug (TDP-3) as supplied to ENI builds upon TCO’s original TDP barrier plug with additional improvements. The patented laminated ISO 14310 V0 certified glass barrier provides a total seal against all fluids under extreme conditions. The plug has been designed and developed to be installed and run as an integrated part of the completion string. This increases the efficiency of the installation process and provides a large bore access when the plug is opened. One of the most important improvements that has been made to the TDP-3 is the addition of rubber bellows, which separate wellbore fluids from the clean fluid in the counter system, improving debris tolerance. The TDP-3 is supplied with a 2 metre debris extension as standard, for use in wells with expected debris issues. Longer extensions can be developed on request.

In addition to being used as a packer setting device, the TDP-3 can also be used as a fluid loss control device, and in most cases as a completion barrier plug to isolate the lower completion while installing the upper completion.

This year, ENI Norge will celebrate 50 years on the Norwegian continental shelf as this prestigious project comes on stream. The Goliat field is expected to be in production for up to 15 years, but the field life may be extended in the event of new discoveries. TCO is proud to be part of the team delivering innovative solutions that improve efficiency and reduce costs.

Author: Silje T. Valskaar, Account Manager ENI Norway