First API 19CI Qualified Retrievable Injection Valve Successfully Installed on NCS

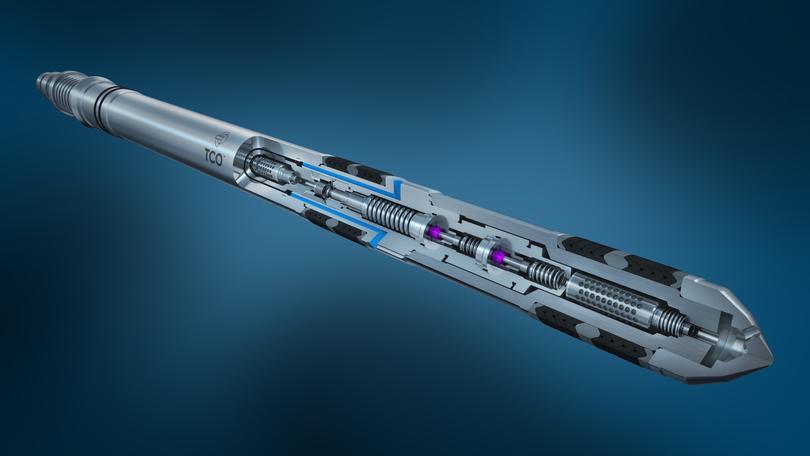

Product: FNR (Fall through protection, Non-return, Retrievable) injection valve

Location: Norwegian Continental Shelf (NCS)

The Challenge

Changing out the valve in a permanent chemical injection system is not as possible as in a more flexible retrievable system. Our customer needed a retrievable chemical injection valve (CIV) in case there were changes in well parameters so a solution had to be developed. The CIV had to comply with the API 19CI standard, have no welded parts, and all components had to be completely machined.

The Solution

To meet the client requirements, TCO developed the FNR (Fall through protection, Non-return, Retrievable) injection valve. The process also involved a collaboration with SLB who supplied the mandrel and running tools in the API test and field trial. The new tool is a retrievable CI system for the side-pocket mandrel qualified according to API 19CI. The technology is based on the already proven permanent CIV from TCO with the back pressure retention mechanism redesigned to meet the requirement of 5000 psi Anti-U-Tube prevention.

The Result

The FNR became the first API 19CI qualified retrievable injection valve to be successfully installed in the NCS. With the ability to retrieve the CIV, the client can conveniently change the valve or Anti-U-Tube mechanism during the well's lifetime. The ISO14310 V0, dual barrier qualified back check valves, ensure a safe and reliable injection system. The FNR has a pressure rating of 10000 psi and can operate at temperatures up to 150 degrees celsius, making it suitable for various applications. The back pressure mechanism confirms the control line's integrity during deployment, showcasing the design's effectiveness.

Conclusion

The FNR injection valve provides flexibility, safety, and reliability, allowing operators to improve efficiency in their operations and save money. The ability to retrieve the CIV and change the valve or Anti-U-Tube mechanism during the lifetime of the well can save operators potential costs of recompleting the well due to CIV failure.

Overall, the development of the FNR injection valve has set a new standard for injection valves and will undoubtedly drive further advancements in the industry, benefiting both operators and the industry as a whole.

Highlights

The FNR injection valve has the following features:

- Redesigned back pressure retention mechanism meeting 5000 psi Anti-U-Tube prevention requirement.

- 10000 psi pressure rating.

- Operates at a maximum temperature of 150°C.

- Uses ISO14998 V0 dual barrier qualified back check valves for valve reliability.

- Ensures control line integrity during deployment with 5000 psi Anti-U-Tube prevention mechanism.