Product: Chemical Injection Valve - HN Valve

Location: Caspian

Challenge

Run an optical fiber cable downhole, to act as a distributed temperature sensor and allow the operator to detect physical parameters of the well production/injection profile.

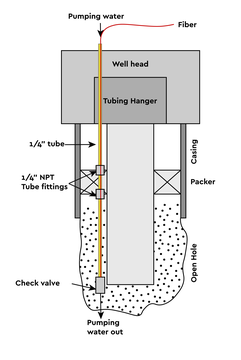

The optical fiber is a very thin string of silica glass with several layers inside. Despite that the fiber is slim, its tensile strength is still very high. The mechanical properties of the fiber, such as its flexibility, enables it to be bent, and therefore to be deployed into a ¼" control line.

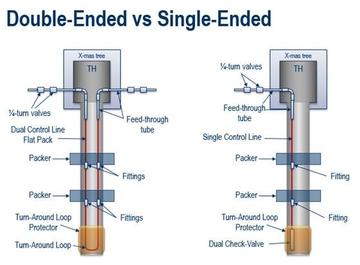

The fiber deployment is performed by pumping a carrier fluid into the ¼’’ control line which inserts the fiber optic through to the end of the control line. An example of the method is to loop the control line back to surface. The method of looping the control line provides the benefit of allowing the fiber to be pumped in return as the control line loop returns at surface. Consequently, if the deployment operation fails, or the fiber breaks, the fiber can be pumped out and new fiber can be re-pumped into the control line.

This specific project had limitations on one control line feedthrough for fiber due to available production packer feedthrough ports. Therefore, looping the control line in the well was not an option. With single ended ¼" control line as the only option, the opportunity of re-deploying another fiber was not available. An additional risk for the single ended option is the added requirement of including a control line barrier from annulus.

With the single ended control line as only available option, this project became an operation with only one chance of success. It was operation critical to have a successful deployment at the first attempt.

This challenge for the service company was compounded with harsh environment conditions present in the well at setting depth 3430mMD, such as: temperatures up to 70˚C, high pressures up to 10kpsi, and various types of corrosive fluids. Also well fluid particles of various sizes and properties including sand and gravel debris could potentially enter the ¼" control line and destroy the fiber or plug the line.

Solution

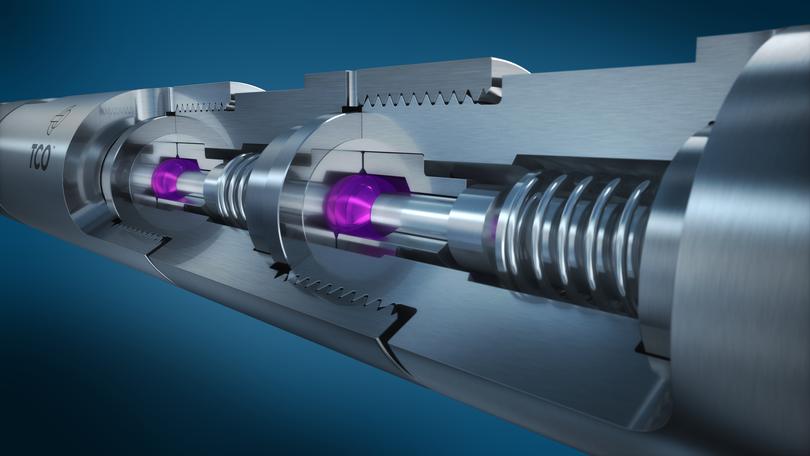

TCO proposed its HN modular chemical injection valve assembly with 3 catch screens and a rupture cartridge. The HN valve includes a dual check valve system to create the required barrier between annulus and control line.

The catch screens are a filtration system with bypass functionality. Two of the catch screens were placed on the inlet end of the valve to catch any debris from the control line during installation. The third catch screen was mounted on the outlet of the valve to mitigate debris from entering the valve outlet during RIH.

Check valve reliability was crucial for the client as to maintain the operator required dual pressure barrier. If these were to fail, the well barrier would be compromised and cement would have to have be pumped into the control line which would cause loss of fiber integrity, hence no data monitoring.

An extensive risk evaluation was performed to justify the design and the use of a single control line with the TCO HN chemical injection valve technology before deployment.

Result

The installation of the control line with the HN chemical injection valve was successfully deployed in the well while running the completion. One month after the control line and valve installation, the fiber optic was successfully deployed to the depth of the check valve assembly.

The addition of the TCO HN chemical injection valve assembly enabled the safe fiber deployment and will ensure that the control line to annulus well barrier is maintained for the life of the well.