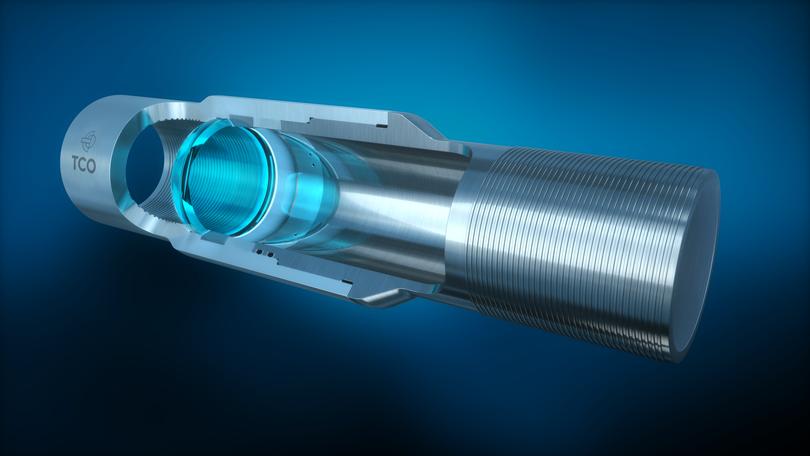

Product: Completion Barrier Glass Plug – Tubing Disappearing Plug – Pump Open (TDP-PO)

Location: Abu Dhabi, Middle East

Challenge

The marketplace has challenges with conventional solutions that are based on remotely operated plugs. These plugs are extremely sensitive to debris with the risk of costly plug opening contingency operations.

Because of this, a client from the Middle East challenged TCO with a requirement of 3-4 Ft debris suspension/ prove the plugs performance in suspension of an 8 Ft. debris column. Debris suspension can be a challenge for many operators during the completion phase, and may cause unefficient operations. To prevent any doubt and ensure that the customer was confident that TCO could deliver as expected, TCO doubled the clients expectation and successfully opened under 8 Ft debris suspension.

TCO's TDP-PO is remotely opened, applying a hydraulic pressure that exceeds its pre-determined shear out value. Compared to competing products available on the market, TCO's barrier glass plug offers the following advantages:

- Debris tolerant opening mechanism

- COst effectiveness

- Leaves no trace in the well after opening (only small particles compared to sand grain size)

- Multiple and reliable contingency removal options

Result

TCO barrier glass plug was heated up to the requested 160 °C. Prior to the debris test, the integrity of the barrier was tested with a stable pressure of 5000 psi. No leakage was observed from any sides of the barrier glass plug.

The barrier glass plug was assembled with a 345 bar/ 5000 psi shear ring. The assembly had a pup joint adding 4,66 meter/ 15 Ft length on top of the glass. A successful 15 minute 276 bar/ 4000 psi pressure test from above and a 345 bar/ 5000 psi pressure test from below was performed prior to loading the plug with debris.

To exceed the client’s requirements of 3-4 Ft of debris, the assembly was raised in vertical position, filled with 8 feet of sand and 9,89 PPG NaCl brine. For the sand mixture to soak up the brine the barrier glass plug assembly was left over night. The assembly was topped up with brine before installed horizontally in the test bay.

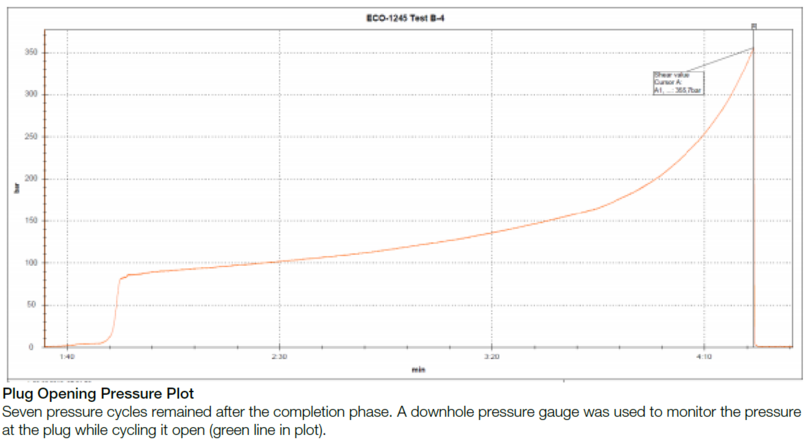

Additionally, to simulate a real well scenario, a gas accumulator for pressure support was added above the plug and below the plug was open ended. The pressure was slowly increased to 345 bar/ 5000 psi to shear out the disc (see illustration below). The shear ring broke and the plug opened at 355 bar/ 5147 psi. The plug had full inner diameter with no glass or sand detected inside of the plug. The glass and debris was fully flushed out during the opening sequence.