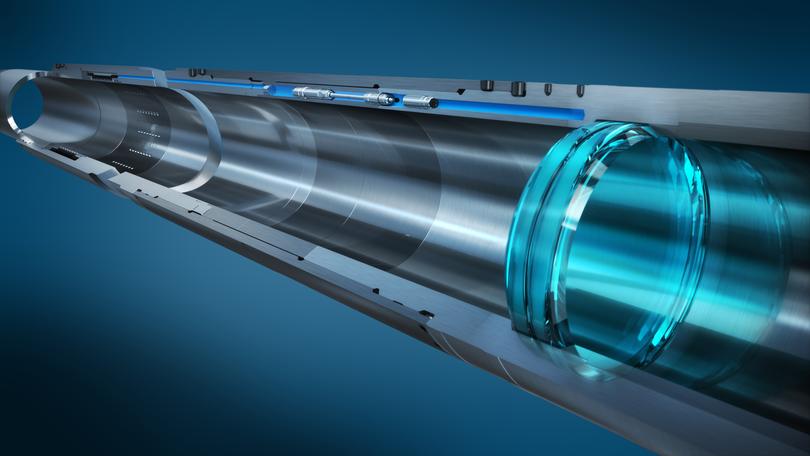

The TDP-NonEx completion barrier device offers operators improved logistics, reduced operational risk and reduced costs while increasing the efficiency of the onsite completion installation process. It has been designed and developed to be installed and run as an integrated part of the completion string or liner.

Product: TDP-NonEx

Location: North Sea, Norway

Challenge

After previously running the TCO TDP-3 587x300 on multiple wells, the customer required larger ID and reduced personnel on board while still keeping the completion intervention free.

Solution

The TDP-NonEx plug was selected as it provided a larger ID bore, did not require personnel onboard and still kept the completion intervention free. A field trial was initiated as this plug had never been run for a Norwegian Operator before.

The TDP-NonEx 587x400 is ISO 14998 V0 validated to 7500psi differential pressure and operating temperature of 20-150°C. It has a robust multi-layer glass pack and the same well-proven debris extension as the TDP-3.

In addition, the pressure cycling system is hydrostatically balanced, meaning that it will adapt to the pressure at true vertical depth, and only top side pump pressure will affect the balanced counter system.

As this is an explosive free barrier plug, both the logistics and work permits are easier to handle, resulting in improved HSE management. The TDP-NonEx plug also gave the added benefit of no TCO personnel required during installation, RIH or opening.

Result

The plug was run as barrier plug with 1,53 sg oil-based mud and was installed as a part of the lower completion. The well was then displaced to seawater before the upper completion and X-mas tree were successfully installed and tested.

The plug was installed at approx. 3400m MD (1979m TVD) with an absolute pressure of 573 bar. It was subsequently remotely opened as planned after 32 days in the well.