Home > Products & Services > Chemical Injection Systems > U-tube Protection

U-tube Protection

U-TUBE PROTECTION

U-tube protection safeguards equipment integrity by preventing pressure imbalances that could harm valves, seals, and tubing.

It also ensures accurate and consistent chemical delivery, which is critical for mitigating issues like scale, corrosion, and hydrate formation. Moreover, maintaining stable pressure conditions enhances operational safety and reduces the risk of accidents. Ultimately, incorporating U-tube protection improves the reliability and longevity of the chemical injection system, minimizing downtime and the need for costly interventions.

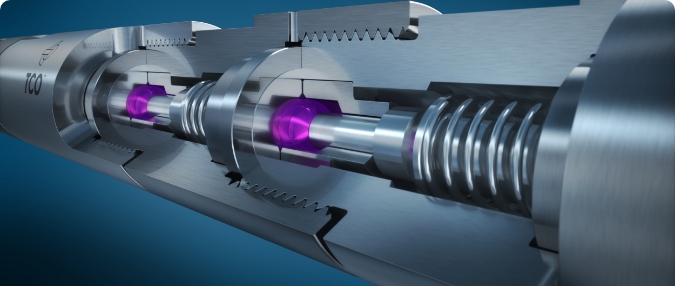

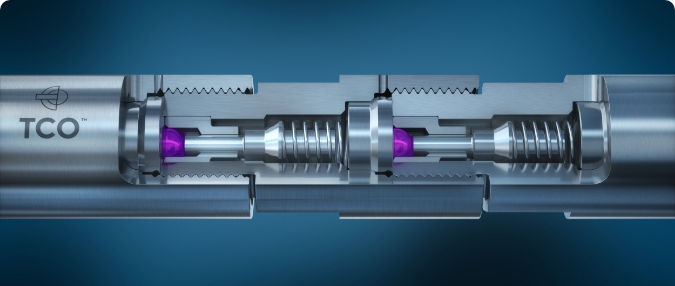

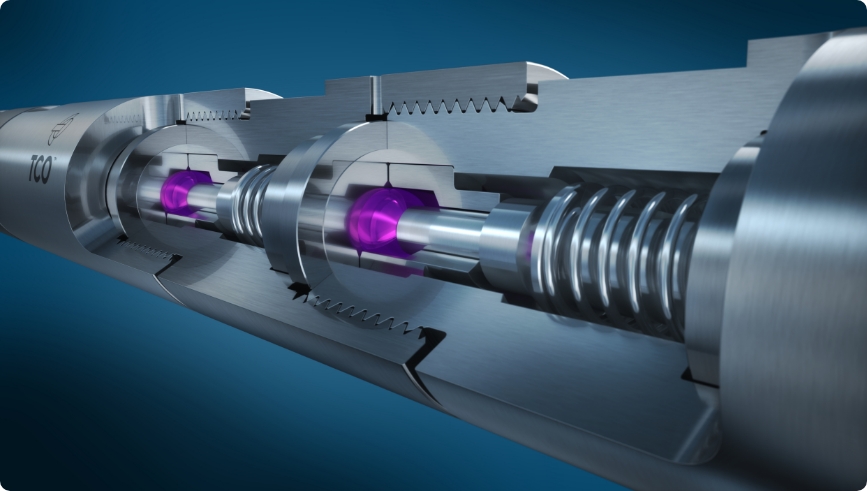

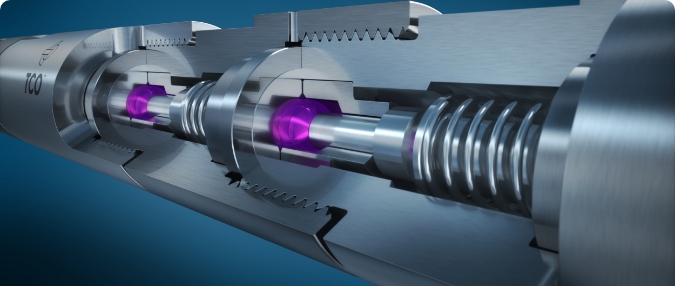

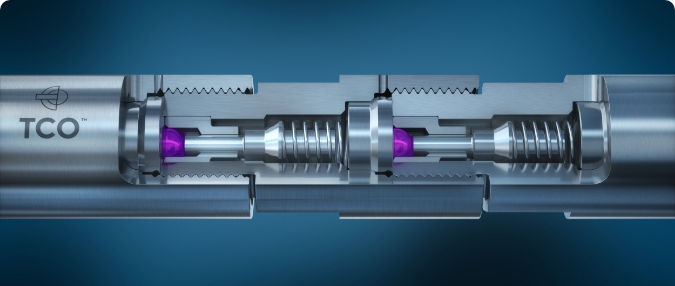

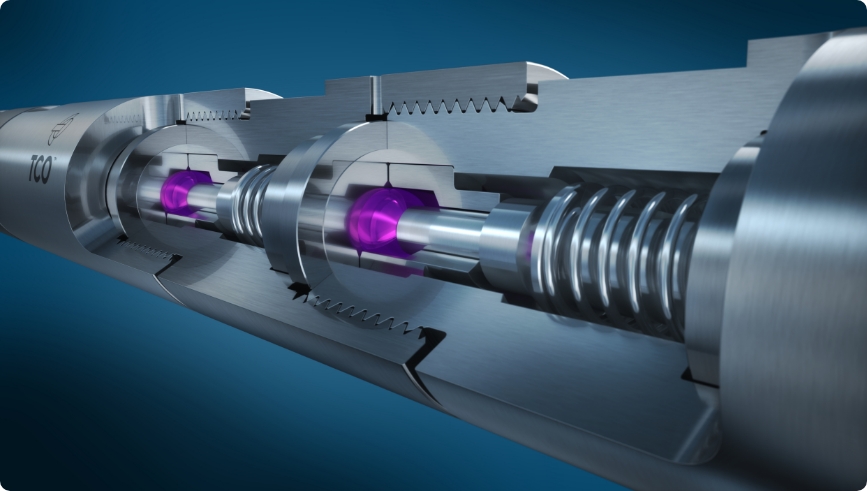

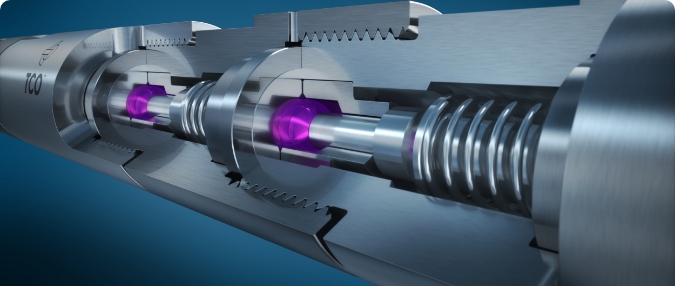

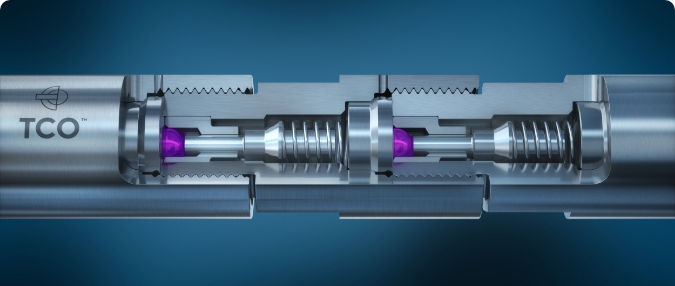

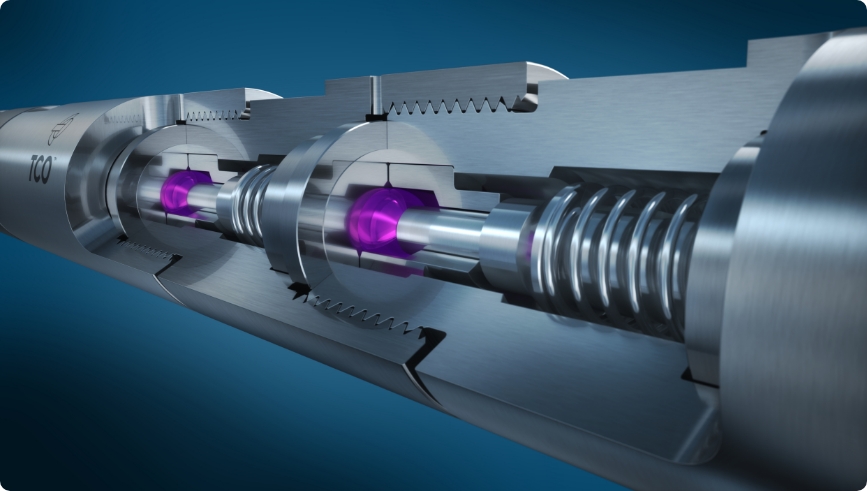

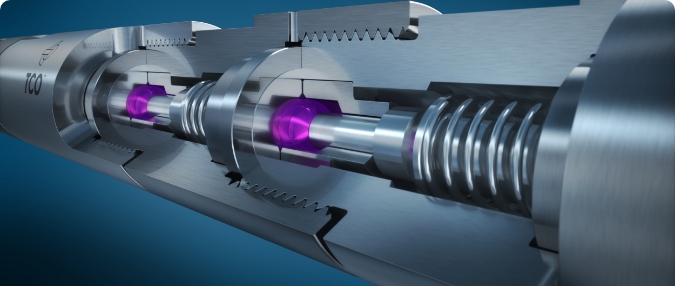

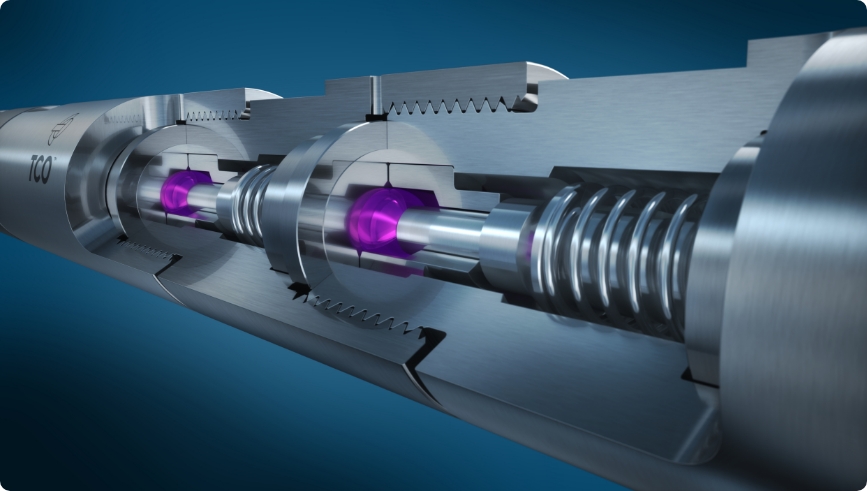

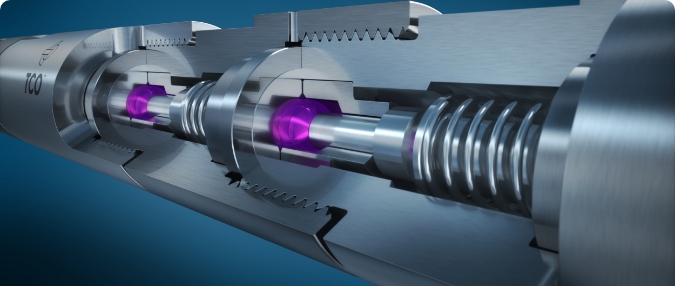

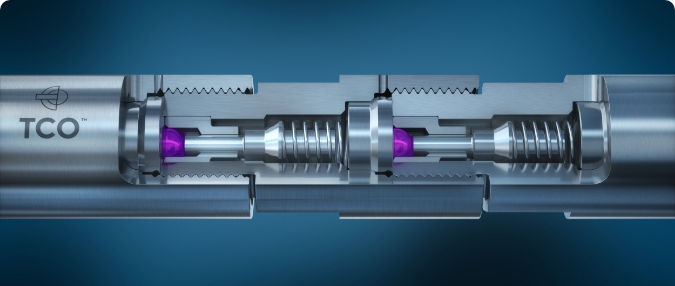

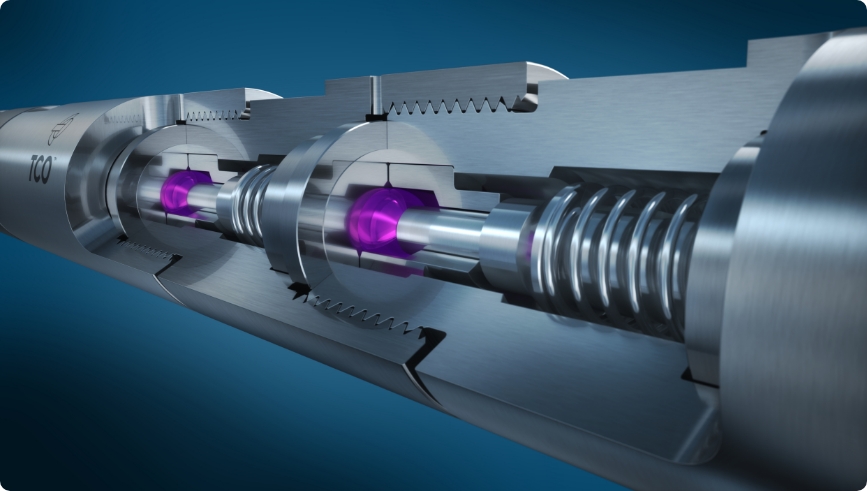

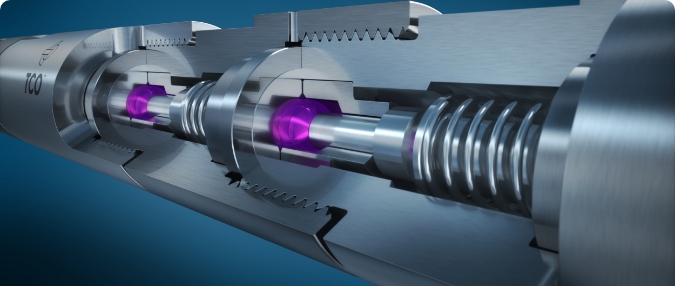

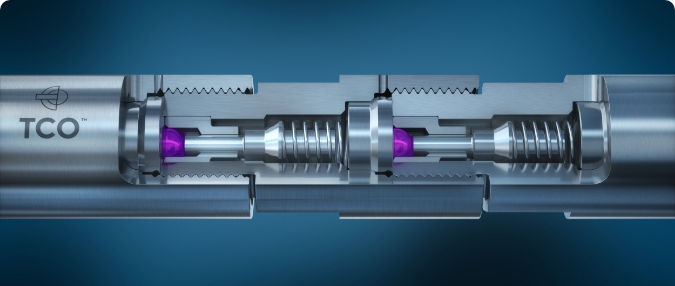

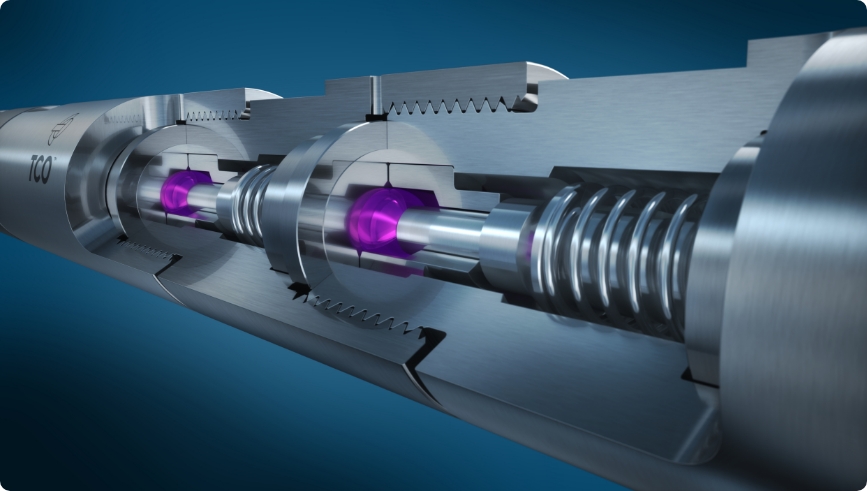

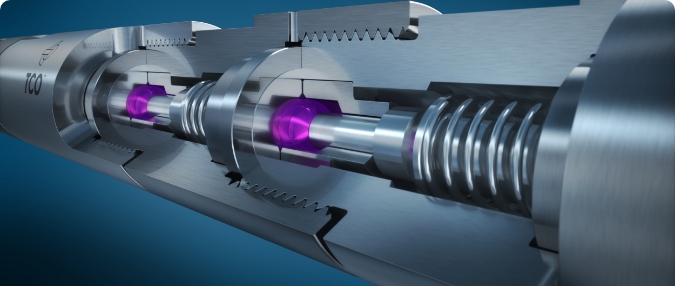

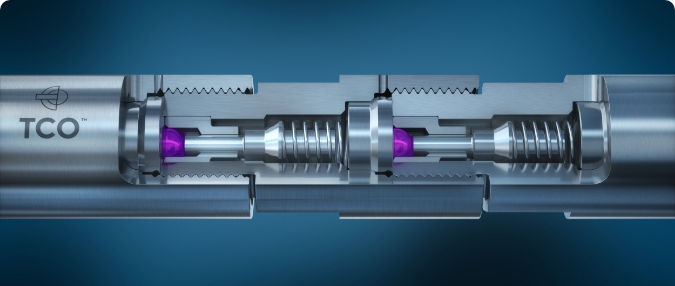

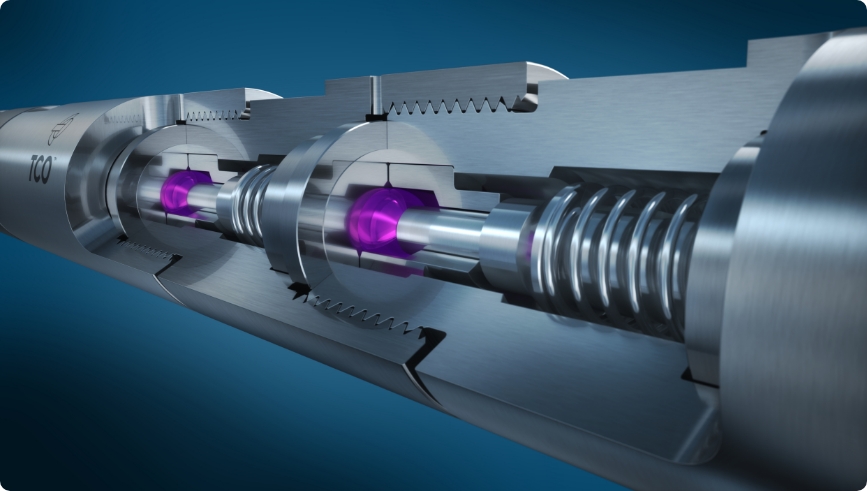

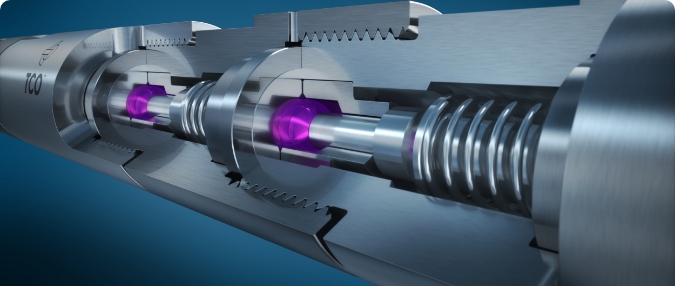

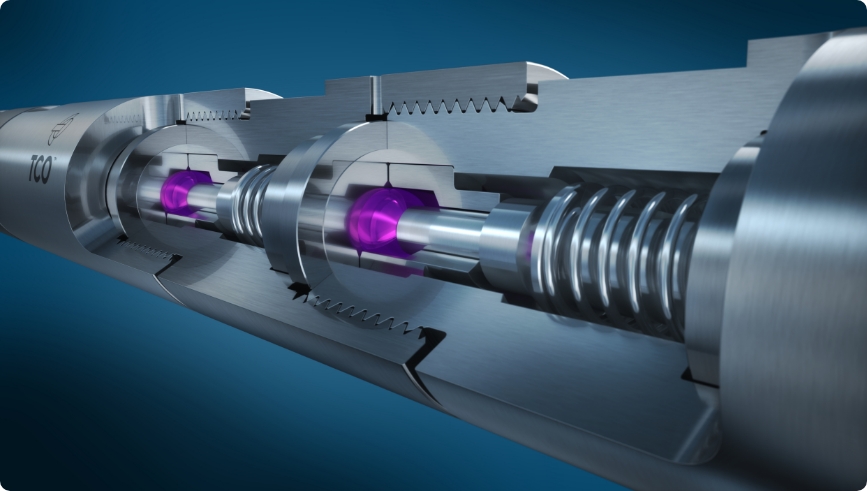

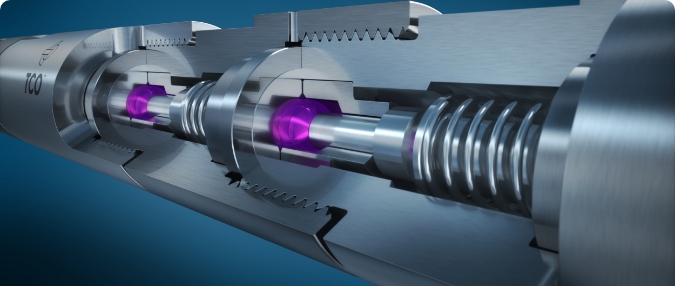

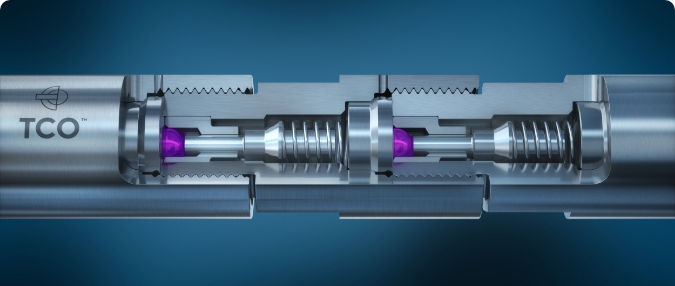

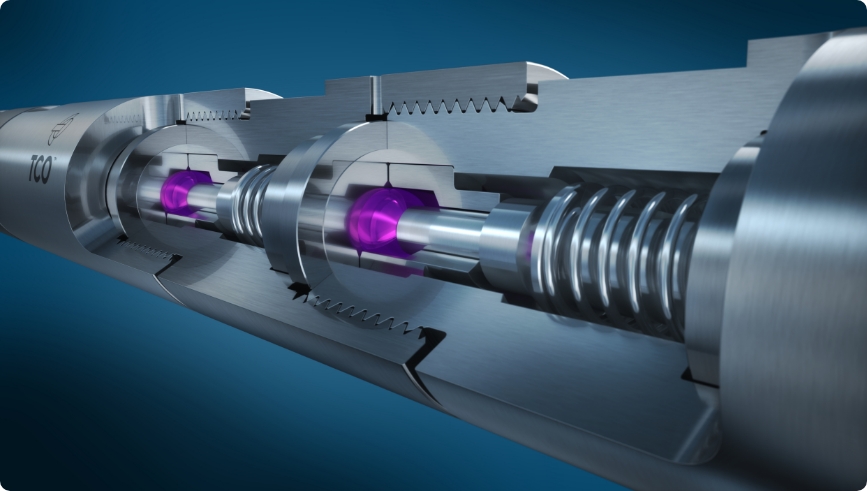

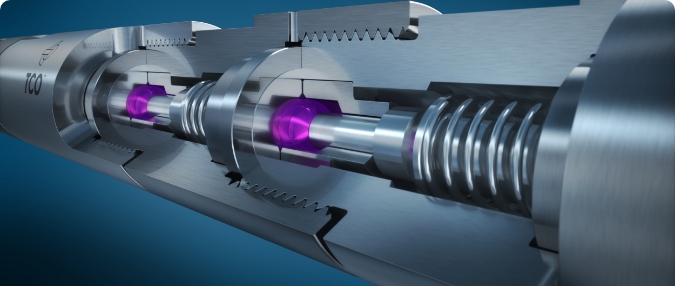

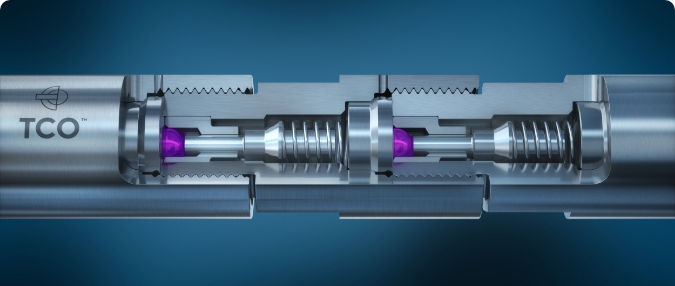

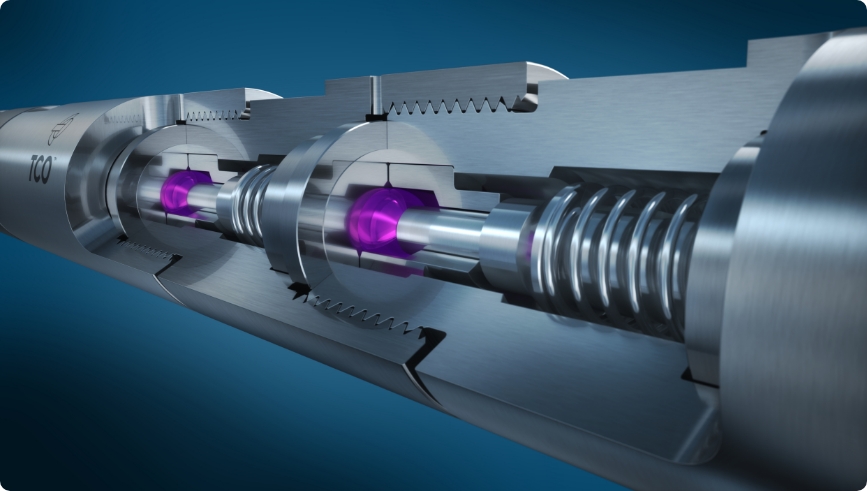

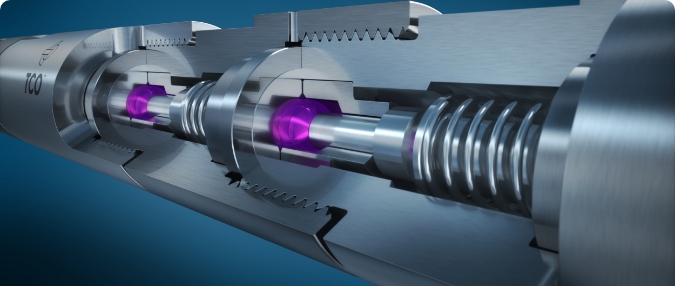

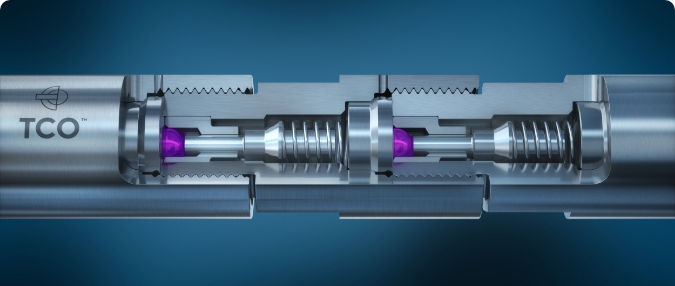

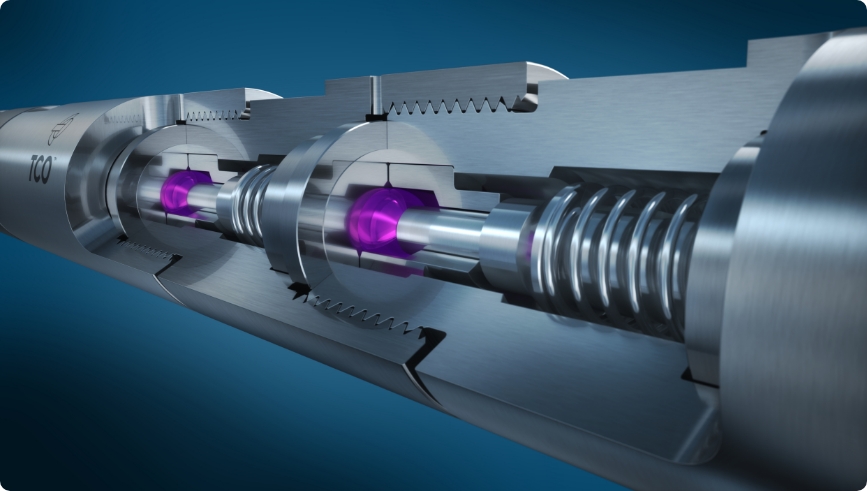

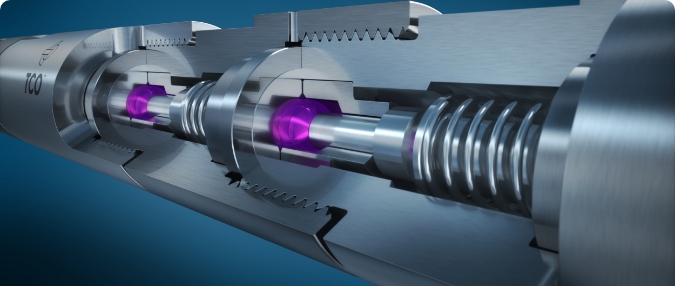

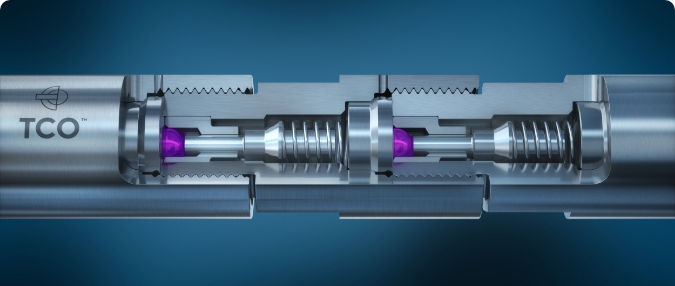

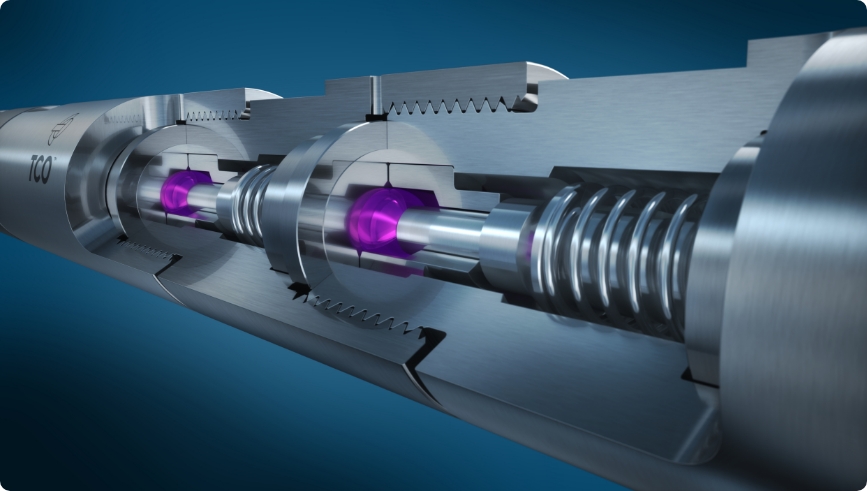

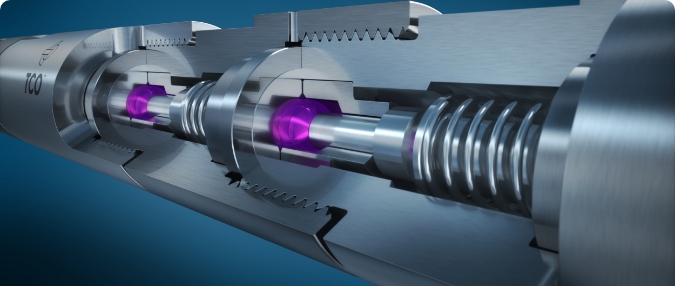

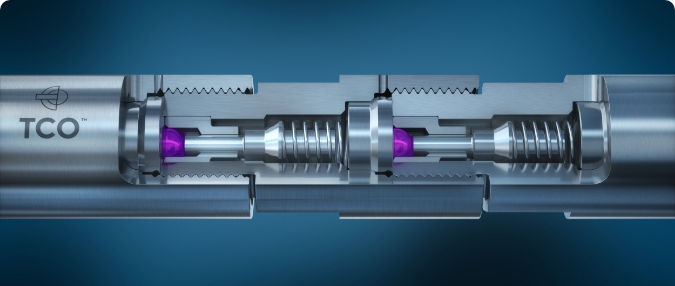

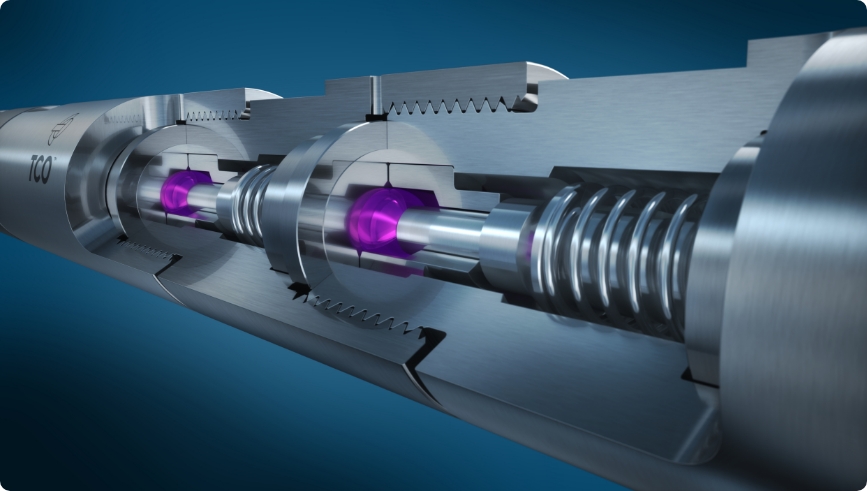

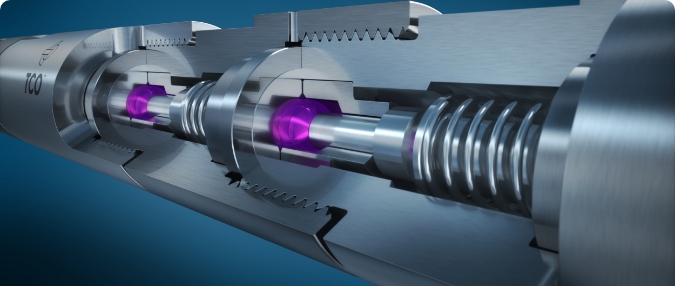

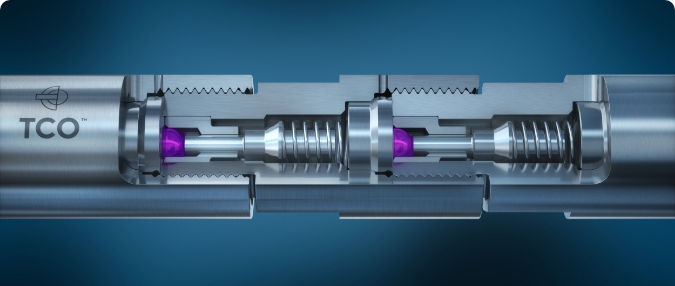

Chemical Injection Valve - FN

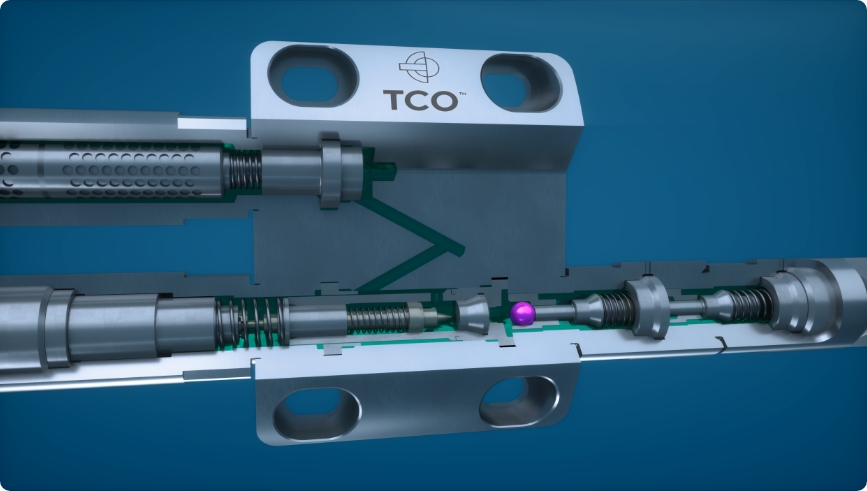

The TCO FN-Series Chemical Injection System provides a reliable solution for chemical delivery in deepwater, ESP, and HPHT wells, specifically engineered to mitigate risks associated with the U-tube effect. This system features a differential pressure valve that provides a closing force proportional to inlet pressure, effectively preventing unintended siphoning of chemicals into the wellbore. It is API 19CI CV1 & TR2385 validated, ensuring compliance with stringent industry standards.

The FN valve maintains a leak-tight seal even in static conditions, making it ideal for wells where chemical flow is intermittent or minimal. Constructed from corrosion-resistant materials and integrated with high integrity metal-to-metal barrier HN checks, the FN system enhances well integrity, reduces the risk of chemical degradation, and supports both tubing and annulus injection configurations.

Its robust design makes it particularly well-suited for offshore wells, artificial lift systems, and depleted reservoirs, where long-term reliability and minimal intervention are critical.

Features

U-tube Protection

High Integrity Non-Return Functionality

Rated for HPHT environment

API 19CI CV1 Validation

Sealed in static condition

Tubing and Annulus injection configurations

Permanent and Retrievable

Benefits

Prevents Chemical Siphoning

Maintains Chemical Efficacy

Enhances Well Integrity

Suitable for demanding environments

Applications

Offshore wells

Deep installations

Depleted reservoirs

ESP completions

Artificial lift completions

High-pressure, high-temperature wells

Tubing or annulus injection

Permanent and retrievable

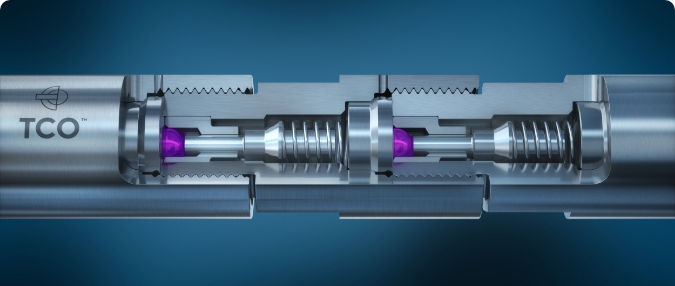

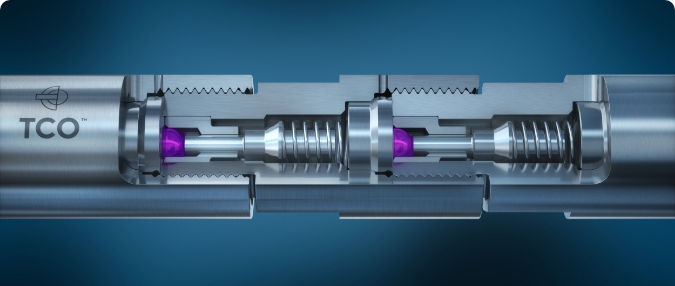

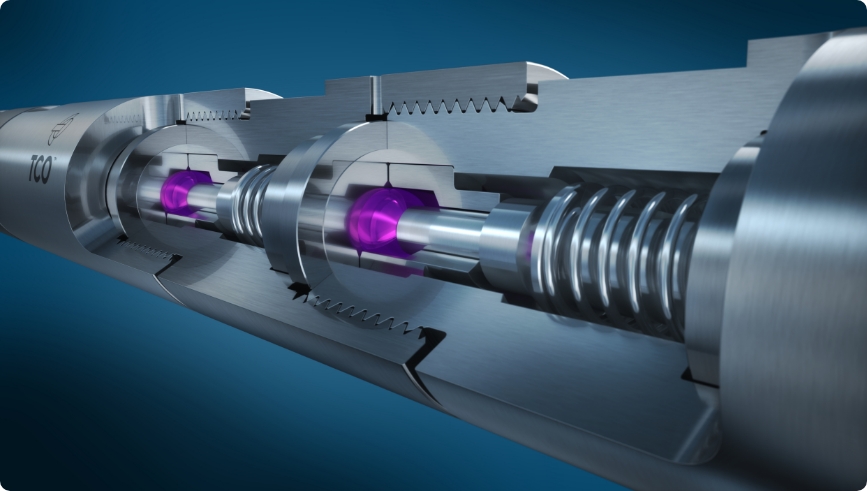

Chemical Injection Valve (FA)

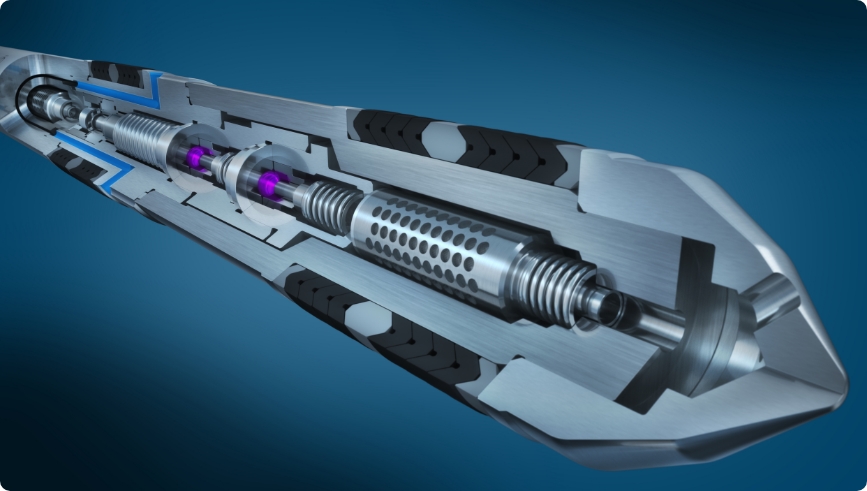

The TCO FA-Series Chemical Injection System is engineered for deep-set and artificial lift applications, offering a smart, self-regulating solution for chemical delivery in dynamic well conditions. Its core feature is a passive-open valve design that allows unrestricted chemicals at extremely low flow during early production, when reservoir and tubing pressures are high, without requiring elevated surface injection pressures.

As the well depletes, the valve automatically transitions into a regulating mode, maintaining consistent chemical injection by providing in-line back pressure support. This design effectively mitigates the U-tube effect, preventing unwanted siphoning of chemicals into the wellbore. Unlike traditional spring-loaded valves, the FA valve imposes no constant restriction, reducing the load on surface pumps and improving operational efficiency. It integrates seamlessly with TCO’s HN-Series barrier valves, ensuring full compliance with well integrity standards.

The FA-Series is particularly beneficial in late-life production and artificial lift systems, where it enhances flow assurance, reduces intervention needs, and adapts to changing downhole conditions without manual adjustment.

Features

Passive-Open U-Tube Design

Self-Activating U-Tube Regulation

API 19CI CV1 Validated

Sealed in Static Condition

Rated for HPHT

Tubing and Annulus Injection Configuration

Modular Integration

Benefits

Prevents Chemical Siphoning

Optimized for Late-Life Production

Maintains Chemical Efficiency

Suitable for demanding environments

Reduced Surface Pumping requirements

Enhance Flow Assurance

Ideal for Artificial Lift Systems

Applications

Deep downhole applications

Artificial lift installations

Deep-set Chemical Injection

High Pressure and High Temperature

Remote or Unmanned Operations

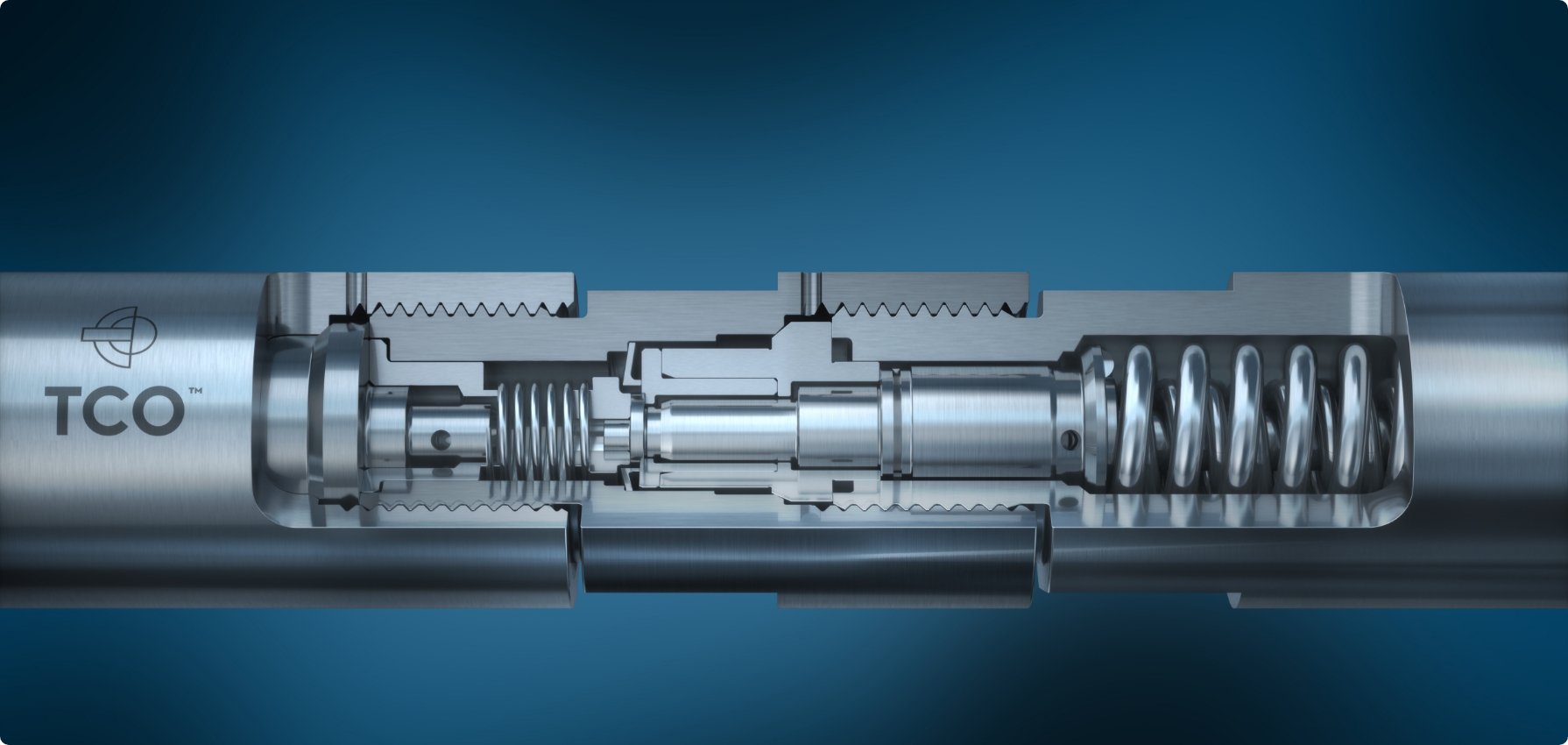

FNR (Retrievable)

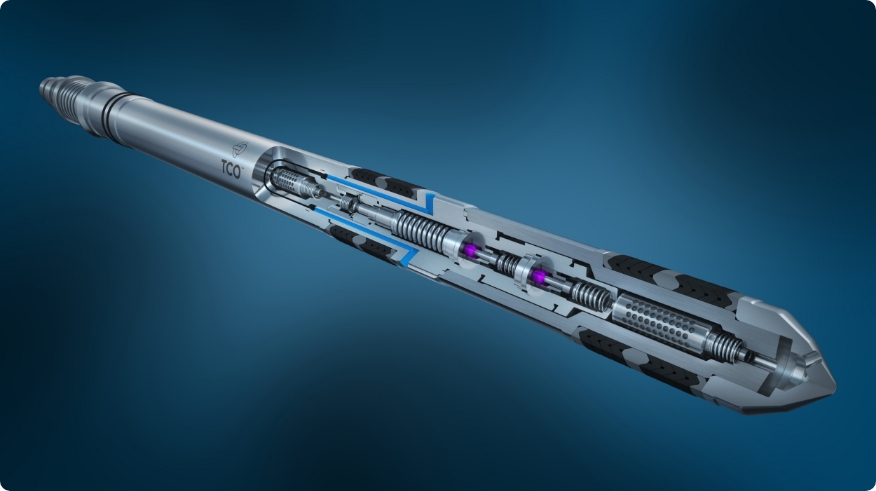

The TCO FNR Chemical Injection System is a high-performance solution designed to ensure safe and efficient chemical delivery in challenging well environments.

It is the first retrievable chemical injection valve to meet the API 19CI standard, offering a combination of U-Tube protection and barrier functionality to prevent the U-tube effect and backflow of chemicals.

The valve is engineered to maintain high backpressure, with a high-pressure rating and high temperature tolerance, making it ideal for HPHT wells.

Its retrievable design allows for wireline-based side pocket mandrel (SPM) installation and replacement, reducing the need for full workovers and enhancing operational flexibility.

Features

API 19CI CV1 Validated

U-Tube Protection

High Integrity Non-Return Functionality

Sealed in Stative Condition

Retrievable design

High Pressure and High Temperature

Benefits

Prevents Chemical Siphoning

Maintains Chemical Efficacy

Enhances Well Integrity

Suitable for demanding environments

Minimizes intervention requirements

Operational flexibility

Applications

Deep installations

Depleted reservoirs

Artificial lift

Dual check valves to complete well barrier envelope

Latch as per running tool requirements

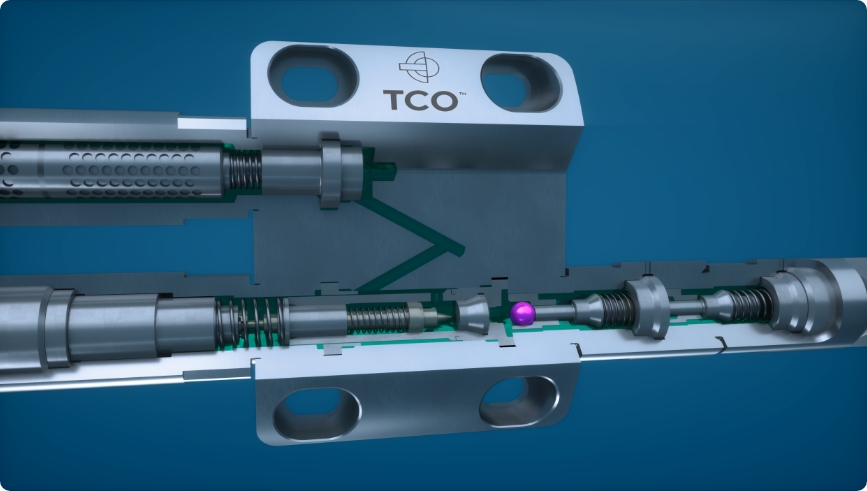

Straddle (Retrofit)

The TCO Straddle Chemical Injection System is a retrofit solution designed to restore chemical injection functionality in wells where the original injection mandrel or valve has failed.

It enables continued use of the existing control line without requiring the removal of the completion string, significantly reducing rig time and operational costs. The system features a specially designed mandrel for completion, used in conjunction with a retrievable straddle packer system to create an annular flow path for chemical delivery.

A side pocket in the mandrel houses a chemical injection valve, typically from TCO’s HN-Series for barrier integrity, and optionally the FN-Series for backpressure support.

The system includes upper and lower seal stacks to isolate the damaged section and maintain pressure containment. This system is ideal for mature or damaged wells, offering a flexible, modular, and cost-effective way to restore chemical injection capability while maintaining well integrity.

Features

Retrofit Capability

Straddle Mandrel Design

Side Pocket for Injection Valve

Seal Stack Integration

High Back Pressure Capability

ISO 14310 V0 Barrier Qualified

Benefits

Restores Injection Capability without recompletion

Re-establish well integrity

Flexible and Modular

Minimizes Downtime

Ideal for Mature or Damaged Wells

Applications

Shut in wells with leaking chemical injection system

Wells with u-tube issues

Seals off leaking valve and continues injection