Annulus pressure buildup (APB) is a well-documented well-integrity hazard, particularly in subsea, HPHT and long cemented wells, where trapped annular volumes can thermally expand or sustain pressure increases. As production begins and well temperatures rise, these trapped fluids expand, causing the annulus pressure to increase. In subsea wells, where annuli are frequently sealed and inaccessible, this buildup can reach levels that exceed the mechanical limits of the casing strings. The consequences can be severe: casing collapse, burst, or loss of well barriers.

Industry studies have shown that APB is most acute in deepwater subsea wells where long cemented sections prevent natural pressure dissipation. For high-pressure, high-temperature (HPHT) wells, even relatively small temperature increases in trapped annular volumes can lead to pressure increases of several hundred bar. Once casing design limits are exceeded, the well’s integrity and long-term productivity are at risk. Conventional solutions have historically included rupture discs, crushable foam, or continuous bleed systems. Each comes with limitations, such as a high costs and the risk of compromising well integrity.

The TCO Annulus Pressure Relief System

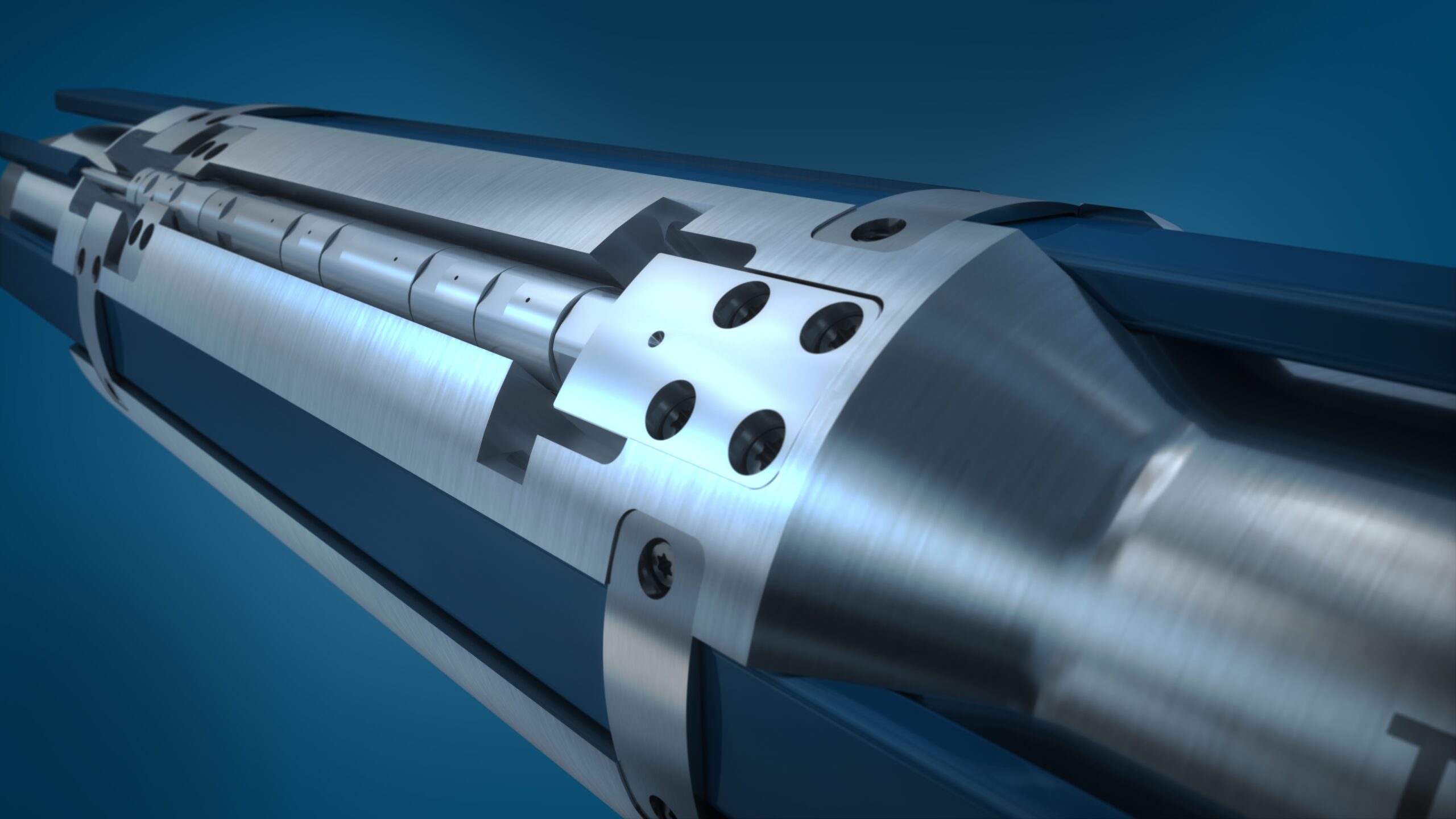

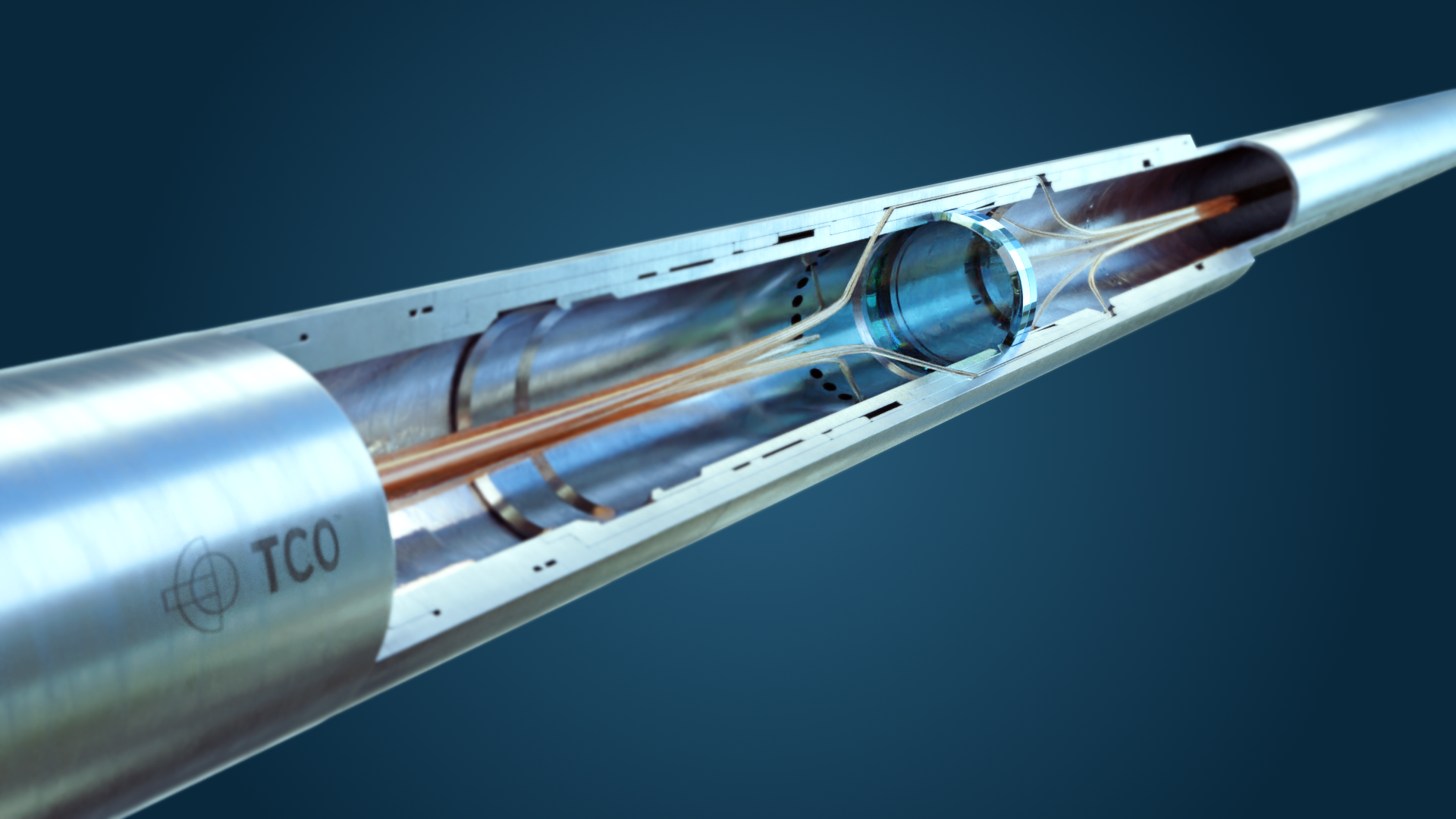

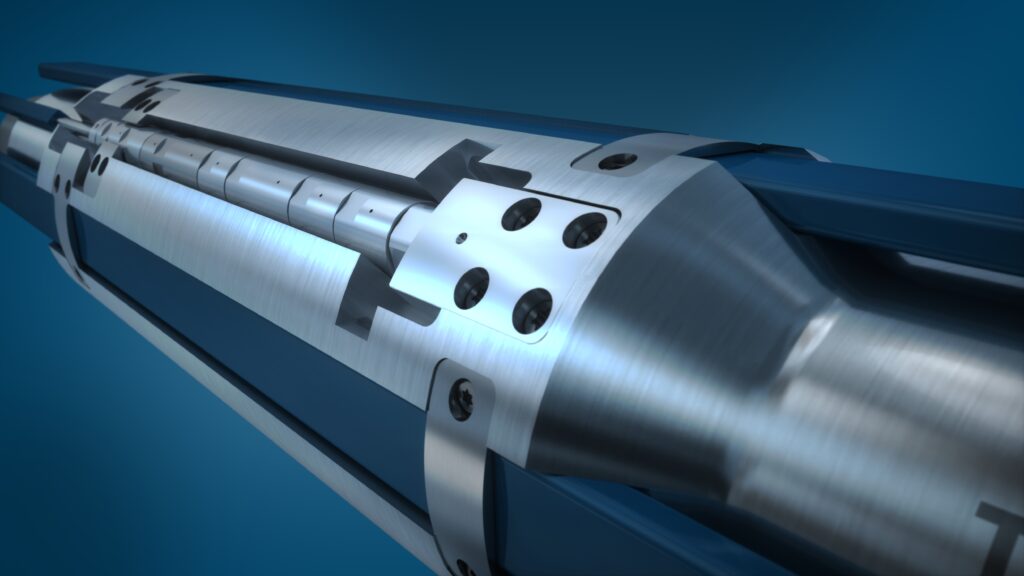

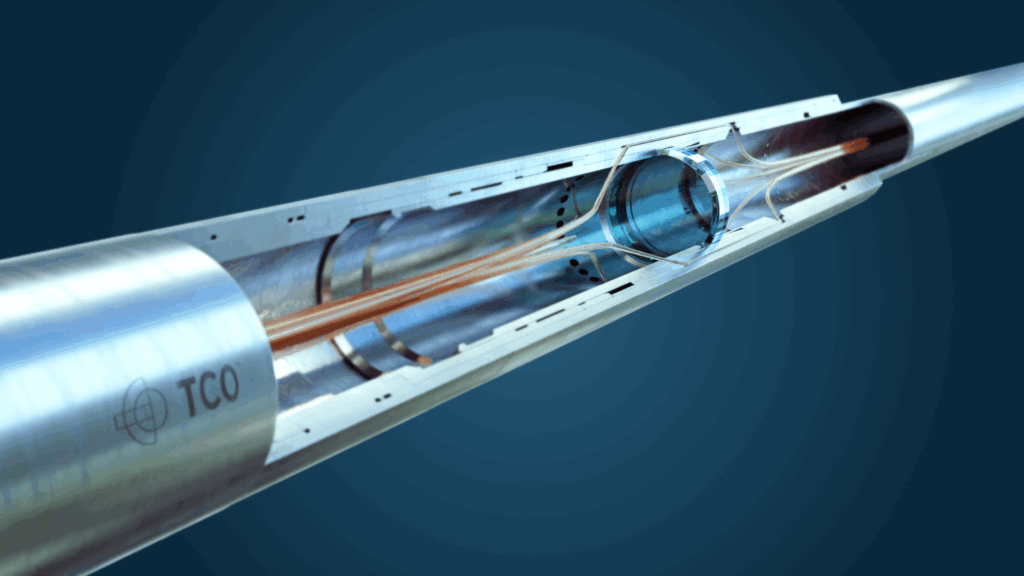

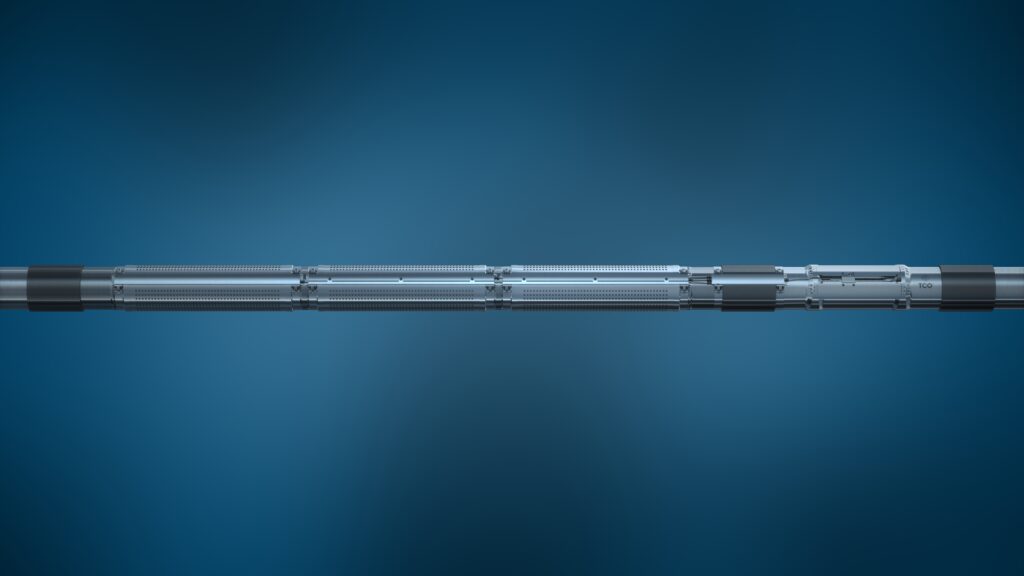

TCO’s Annulus Pressure Relief System (APRS) was developed to address these shortcomings with a more reliable and controllable method of annulus pressure management. The system is integrated directly into the production casing string and combines a patented relief valve mechanism with gas-tight check valves and an integrated filtration unit. It is fully certified to ISO 14998 V0 standards and qualified to Equinor TR2385 requirements, ensuring gas-tight barrier performance under demanding subsea conditions.

The key principle behind the APRS is controlled, one-way relief. Unlike systems that continuously vent annular pressure, the APRS valve opens only when the B-annulus pressure exceeds a pre-determined absolute threshold. Integrated check valves ensure there is no backflow from A to B, preserving barrier integrity. The filtration system prevents solids or debris from interfering with valve operation, an essential safeguard in wells where intervention is difficult or impossible.

This design offers several advantages. By controlling pressure rather than allowing uncontrolled or continuous venting, the APRS prevents both casing collapse and burst, maintains the production tubing barrier, and avoids introducing unnecessary transfers between annuli. It also simplifies installation, since it is run as part of the casing string with no need for external lines or sacrificial devices.

Case studies:

- Norwegian Sea

The value of APRS has been demonstrated in multiple subsea applications. In one case in the Norwegian Sea, a major operator experienced a trapped volume between the 9 7/8” and 13 3/8” casing strings during cementing operations. The result was a closed B-annulus volume with 250 bar trapped pressure. Thermal expansion during well startup was expected to raise this pressure to 550 bar, creating a high likelihood of collapse in the 10 ¾” casing.

The original mitigation plan relied on an open shoe design to bleed excess pressure into the formation. However, due to a long cement job and the risk of plugging, the shoe became cemented off, removing the intended relief path. Faced with the risk of casing collapse, the operator sought an alternative solution.

TCO’s APRS was mobilized and installed as part of a casing patch operation. The 9 7/8” casing was cut and re-patched, with the APRS positioned just below the 10 ¾” tubing hanger. The valve was pre-set to open at 210 bar, ensuring that B-annulus pressure could never exceed that differential relative to A-annulus pressure. Once installed, the system operated as designed, relieving excess B-annulus pressure during startup while maintaining casing support. This avoided suspension or plug-and-abandon operations and enabled the well to be completed on schedule. - UK North Sea

Another deployment took place during Apache North Sea’s conversion of the Callater subsea discovery well, 9/19b-18X, to production. The drilling team identified the need for a mechanism to relieve temperature-induced B-annulus pressure buildup throughout the well’s production life, with the added requirement that the solution remain compatible with potential future gas-lift operations.

The APRS was selected and installed as part of the 9 5/8” casing string, positioned approximately 270 ft below the wellhead inside the 13 3/8” casing. Prior to installation, the wellbore was cleaned and displaced to treated seawater to minimize residual solids. Both A and B annuli were pressure-tested to confirm integrity.

When the well was later brought on stream, pressure data confirmed that the B-annulus vented effectively into the A-annulus as the APRS activated. The well ramped up to production of approximately 21,000 BOE per day without any casing pressure issues. This marked the first deployment of APRS technology in the UK sector and provided further validation of its reliability in subsea operations.

Implications for Subsea Well Integrity

The management of annulus pressure becomes more significant as the industry develops deeper, hotter, and more complex subsea wells. Trapped annular pressure remains a leading contributor to well integrity failures, and solutions that rely on sacrificial components or continuous venting are increasingly seen as inadequate.

By embedding a controllable, downhole relief mechanism directly into the casing design, operators can manage annulus pressure buildup without compromising barriers or relying on uncertain intervention options. For subsea wells where access to annuli is limited and the cost of remedial work is high, this provides a clear advantage.

Field deployments since 2013 have demonstrated both the reliability and flexibility of the APRS. The system has been applied in wells with trapped annuli, subsea wells with limited intervention access, and sour service wells requiring robust barrier integrity. In each case, the result has been the same: controlled relief of annulus pressure, prevention of casing collapse, and preservation of long-term well integrity.

As subsea developments extend further offshore and into more challenging reservoirs, the industry will continue to face the invisible but critical threat of annulus pressure buildup. TCO’s Annulus Pressure Relief System offers a proven and practical way to address this challenge, ensuring that wells remain safe, reliable, and productive throughout their lifecycle.