Home > Products & Services > Chemical Injection Systems

Chemical

Injection Systems

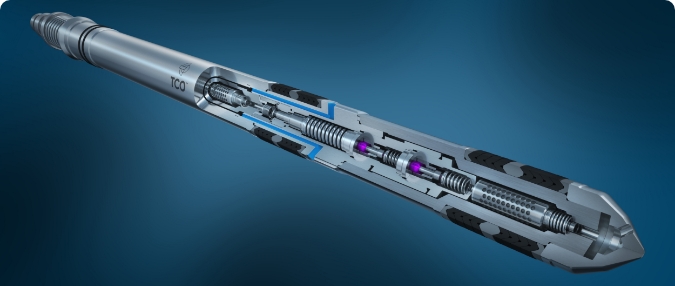

By incorporating TCO Chemical Injection Systems – the world’s only API 19CI qualified CI system – into well completions, operators can sustain production, maintain optimal system flow, as well as reduce corrosion and costly downtime.

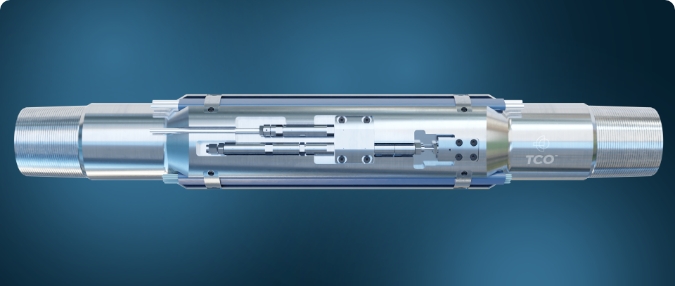

Our Chemical Injection Systems inject directly into the wellbore, annulus, or reservoir to control chemical reactions. Performance is continuously monitored and adjusted to ensure optimal performance and safety.

In addition to chemical delivery, the system also acts as a pressure barrier between the control line and well flow. It protects the control line from hydrostatic fall-through and vacuum conditions – ensuring system integrity in even the most demanding environments.

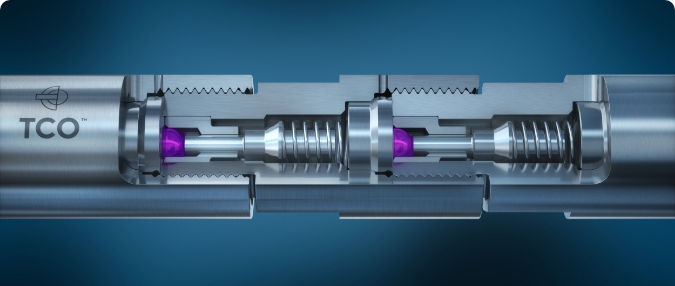

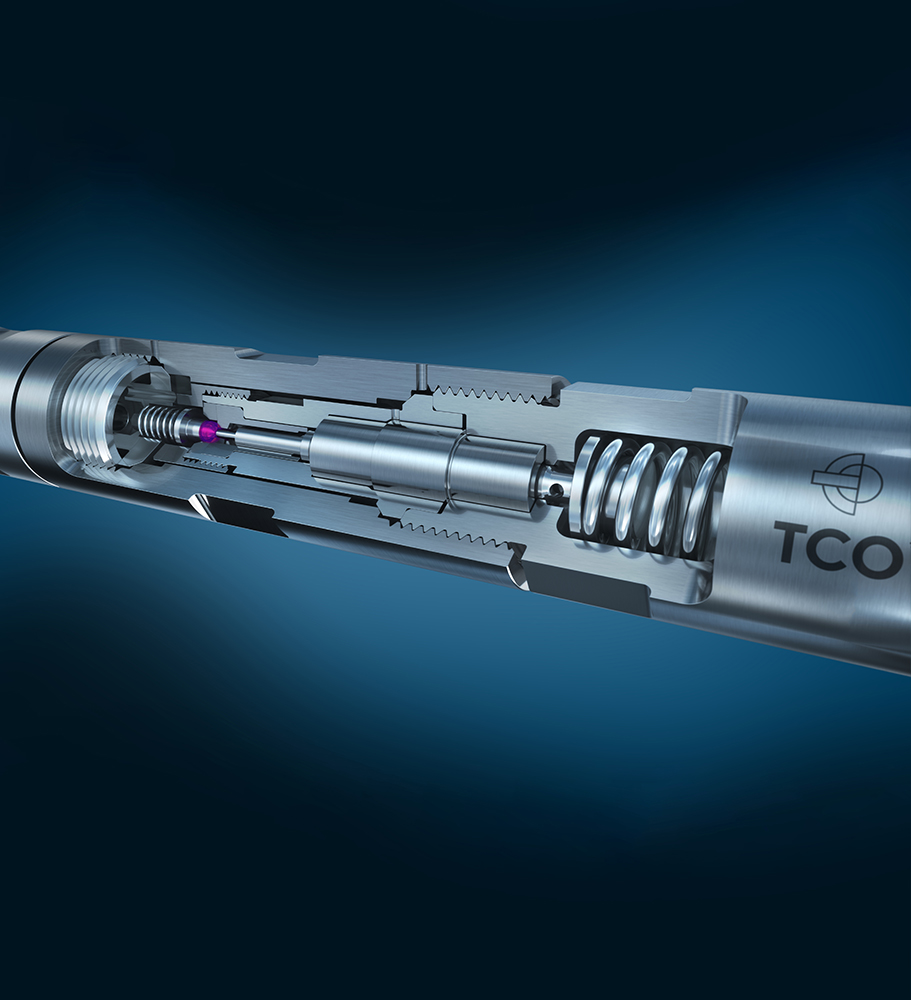

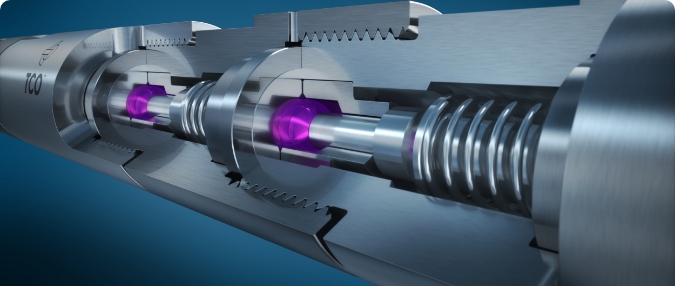

Our modular Chemical Injection Systems feature dual check valves for barrier protection, catch screen to protect valve function and internal pars, a back pressure module for U-tube safeguarding, and constant-rate distribution for reliable, long-term performance. Every element is engineered for precision, safety, and efficiency in modern well completions.

The Q-series valve enables single-line chemical injection across multiple zones, maintaining a pre-determined, fixed flow rate for smart completions - regardless of pressure changes.

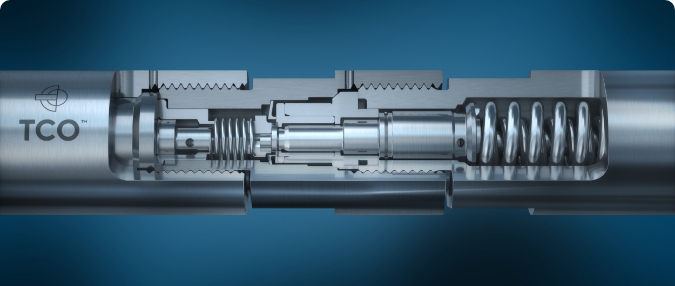

U-tube protection prevents pressure imbalances, protects equipment, and ensures precise chemical delivery against scale, corrosion, and hydrates.

Accessories designed to enable a smoother running and set up of the Chemical Injection System.

HN Module

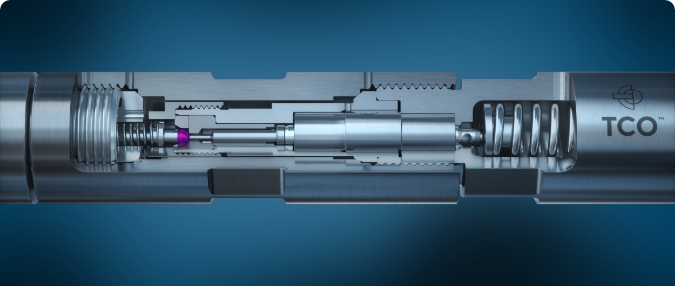

API 19CI V1 validated to provide barrier between tubing and annulus/control line.

FN Module

API 19CI V1 validated u-tube protection ensuring steady state chemical injection over the life of well.

FA Module

API 19CI V1 validated u-tube protection enabling continued injection when surface pump pressures are low.

Q Module

Enables precise, fixed-rate chemical injection to multiple zones through a single control line.

Features

Barrier Validated

Fall-Through Protection

Permanent and Retrievable Configurations

High Integrity, Non-Return Functionality

Fixed Flow Control Across Multiple Zones

Deep.set and Artificial Lift Compatibility

Modular Accessories

Benefits

Production Flow Assurance

Prevents Hydrate Formation, Scale build-up, Paraffin Deposition, and Corrosion

Reduced Downtime

Extended Production Cycles Applications

Demulsification

Upper and Lower Completion Deployed

Permanent or Retrievable Ssystem

Applications

High pressure, High-temperature Hostile Environments

Offshore Wells

Deep Installations

Depleted Reservoirs

Tubing or annulus Injection

When you need us

Our global presence means we’re ready to implement our solutions whenever and wherever you need them. Get in touch with a member of our team today.

Get in touch

Our global presence means we’re ready to implement our solutions whenever and wherever you need them.

Get in touch with a member of our team today.