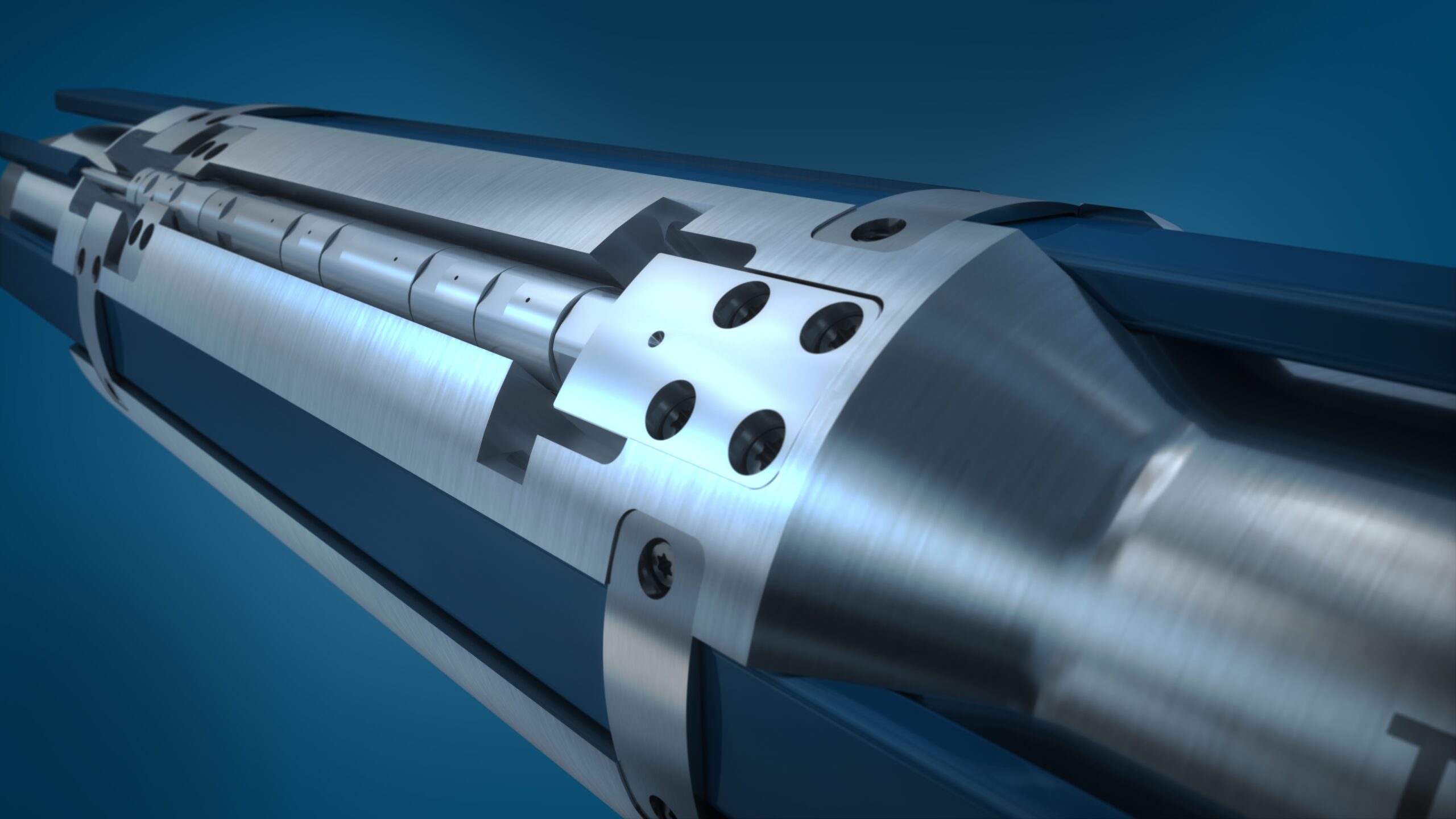

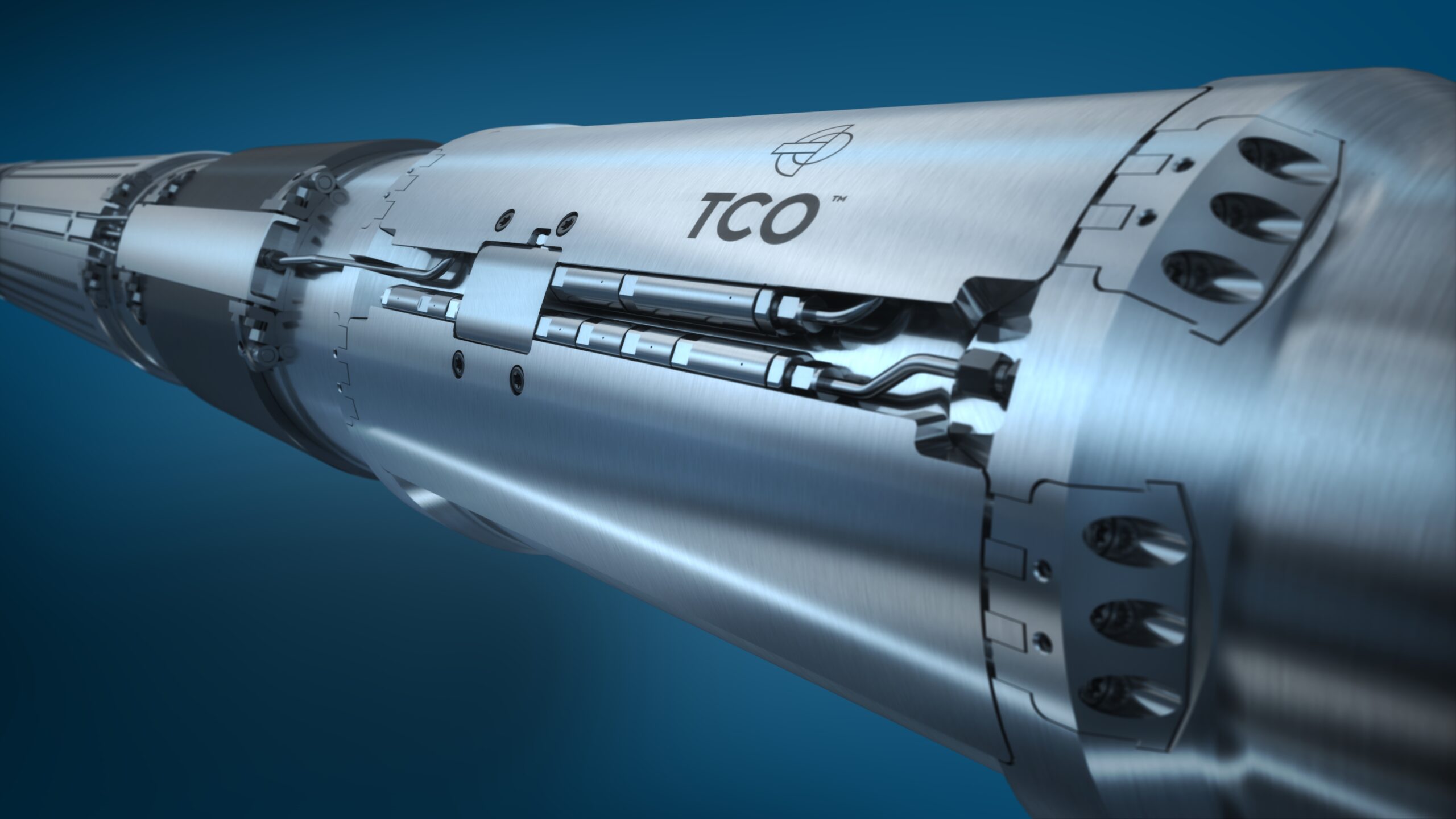

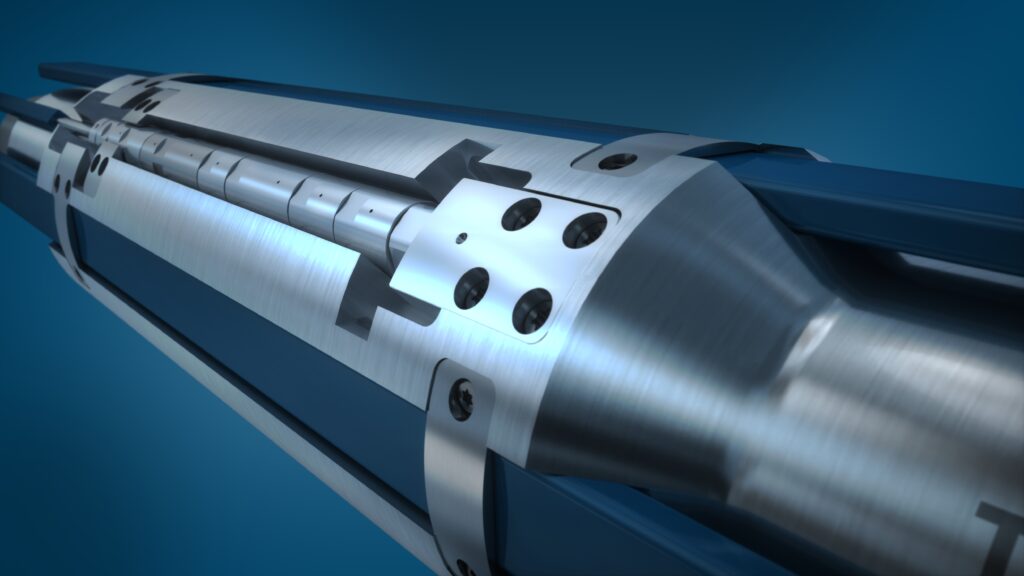

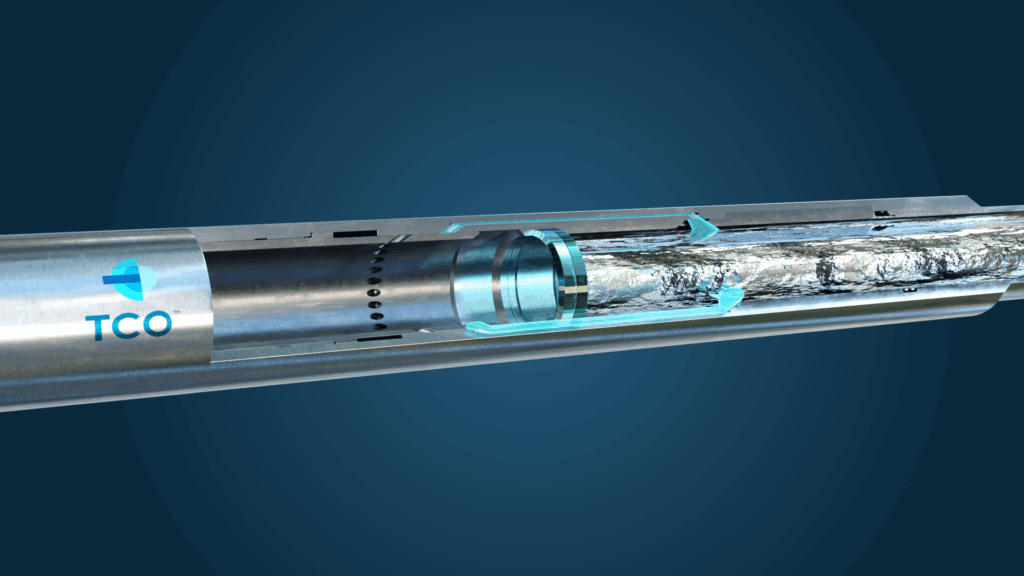

Operators face growing pressure to reduce well completion times, minimize fluid losses, and improve safety without compromising on efficiency. TCO’s Deep Set Bypass Plug (DSBP) responds to that challenge with a smart and versatile solution. Unlike traditional solutions that trap pressure or require mechanical intervention, the DSBP offers full circulation capability during deployment and a reliable seal when needed, without leaving hazardous pressure below the plug.

As the inventor of the original glass plug, TCO has built on years of experience to engineer the DSBP as a remotely activated barrier plug that combines proven mechanical systems with intelligent technology. It’s a plug designed to optimise isolation.

Glass Plug Technology

While other isolation tools on the market may introduce constraints such as reduced internal diameters, mechanical complexity, or the risk of trapped pressure, the DSBP is purpose-built to eliminate those compromises.

What stands out is TCO’s unique E-trigger system, which is a highly selective, pre-programmed activation mechanism that allows the bypass sleeve to close remotely at precisely the right moment using a unique pressure key.

The DSBP also integrates a balanced mechanical counter that enables remote opening using pressure cycles. This allows for a full bore access without milling or intervention. Designed to operate reliably in hostile environments and rated to ISO 14998 V0 standards, the DSBP combines high-integrity sealing, intelligent actuation, and flow flexibility in a compact, formation-friendly package that outperforms conventional isolation tools in both safety and efficiency.

A Problem Worth Solving: The Story Behind the DSBP

The idea for the DSBP was born from necessity. In a vast offshore field in the Middle East, a major operator was facing a recurring and expensive challenge. Each time the lower completion was installed, and the filter cake breaker fluid was spotted, the well began to lose thousands of barrels of expensive, inhibited brine to the formation – up to 8,000 barrels per well.

The operator approached TCO with a clear mandate: develop a solution that could isolate the lower completion after the filter cake breaker had been spotted, without losing control of the well or sacrificing operational flexibility.

TCO responded by creating the Deep Set Bypass Plug. Leveraging its expertise in glass plug technology and building on components with proven track records, TCO engineered a remotely activated plug that allowed fluid to be pumped past the glass barrier during deployment, then close via a signal-triggered sleeve to establish a high-integrity V0-rated seal. The result was a tool that not only solved the immediate problem but also opened new possibilities for smarter well completions in other scenarios too.

Three scenarios that highlight the versatility of the DSBP:

- Accelerating Completion Timelines in the North Sea

In the North Sea, where operators try to target 20-day well completions, the DSBP has become a critical enabler. By deploying both shallow and deep set plugs, operators are able to move through completion stages without intervention delays. The DSBP’s remote activation and auto-fill capabilities allow teams to transition seamlessly from lower to upper completions while maintaining well integrity and operational momentum. - Preventing Fluid Losses in the Middle East

The field in the Middle East that inspired the DSBP’s development continues to benefit from its deployment. By isolating the reservoir after spotting the filter cake breaker fluid, but before running the upper completion, the DSBP has effectively eliminated up to 8,000 barrels of brine loss per well. This not only results in substantial cost savings, but also reduces stress on the formation and enhances overall well safety. - Managing Complex Completions with Multiple Control Lines

In an ongoing North Sea operation, the DSBP is proving its value in one of TCO’s most technically challenging completions to date. The well design features multiple control lines and requires a compact, debris-tolerant isolation solution with remote actuation. The DSBP has been integrated seamlessly into the lower completion string, with its intelligent activation system enabling precise control and robust sealing without compromising the completion envelope. The operation continues to demonstrate the plug’s capability to meet the demands of next-generation well architectures.

Enabling safer, cleaner, and faster completions

As completions grow more complex, technologies like the Deep Set Bypass Plug are becoming a necessity. Its ability to provide programmable, full-bore isolation while simplifying operations makes it an essential component of modern well design.

Whether it’s eliminating fluid losses, achieving ambitious completion timelines, or navigating complex downhole environments, the DSBP is redefining what’s possible in well isolation.

Suggested break out box:

Its functionality is enabled through a unique set of technologies:

- A high-strength, V0-qualified glass barrier disc

- A full-bore bypass sleeve that allows high-rate circulation (up to 10 bbls/min)

- A pre-programmed E-trigger system for remote closure

- A multi-cycle mechanical counter for remote plug opening

- A debris-tolerant, pressure-balanced design for maximum reliability

The result is a flexible tool that enhances well integrity and dramatically reduces operational risk.