Corrosion is often called the “silent tax” on production, and Rystad Energy estimated intervention spending at roughly US$58 billion in 20231. Beyond the direct costs, corrosion can lead to catastrophic failures, environmental disasters, and significant downtime, all of which exacerbate financial losses. Even minor degradation can constrict flow paths, increase pump load, and wear down seals and valves. Chemical injection is at the heart of a proactive approach to corrosion management. By delivering inhibitors, scale preventers, demulsifiers, and other treatments directly into the wellbore, annulus, or reservoir, operators can stop the slow creep of corrosion before it undermines production.

The Growing Role of Chemical Injection in Well Integrity

This is no longer an experimental technique. In a SPE paper2, an operator said that 30–40% of new wells over the last decade were equipped with downhole continuous injection, with scale inhibitors accounting for three-quarters of those installations. Scale, in particular, remains the most common and persistent threat, and injection systems are now seen as essential safeguards in long-life completions.

Engineering Design: The Foundation of Reliable Chemical Injection Systems

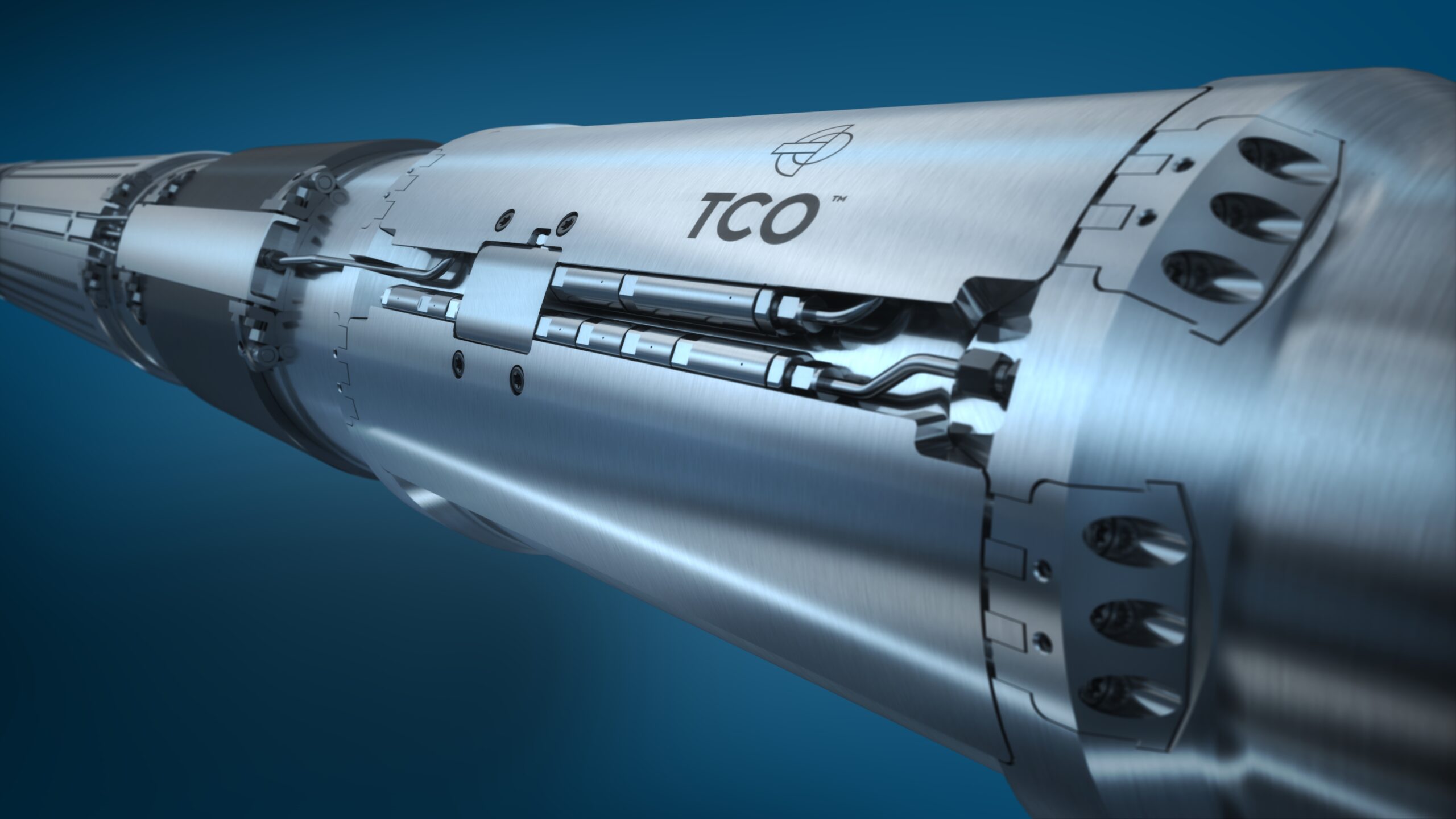

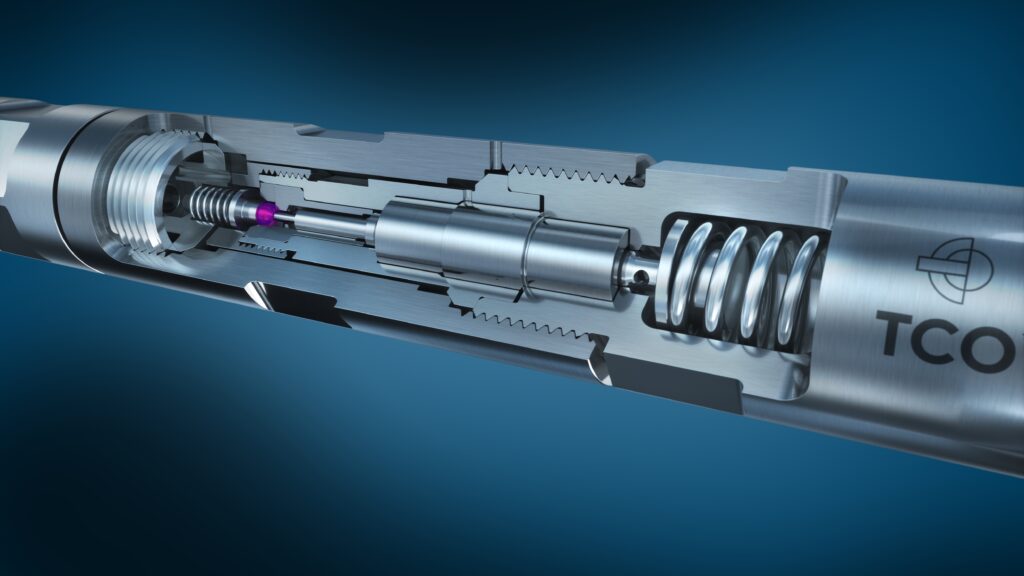

Design, however, is critical. The same SPE study highlights why robust engineering is needed. Thin control tubing can suffer evaporation at gas-liquid interfaces, producing localized precipitation that clogs lines. To prevent uncontrolled U-tubing or siphoning, paired check-valve arrangements are often used. TCO’s Chemical Injection Systems embodies this technology. Our modular architecture turns a single control line into a distributed delivery system, combining validated barrier modules with intelligent valves that adapt to changing reservoir conditions.

Smart Valve Technology: Precision and Protection in Every Completion

HN valves act as dual check barriers, safeguarding flow paths between the tubing and annulus. FN valves stop siphoning and prevent chemicals from unintentionally draining through the system. FA modules introduce a passive, self-regulating function, delivering unrestricted flow when reservoir pressures are high, then automatically adding back-pressure as pressures decline. The Q-Series extends this control by distributing fixed-rate injection across multiple nodes along a single control line, ensuring even coverage in multi-zone completions. Working together, these modules turn chemical injection into an engineered safeguard, protecting well integrity while supporting reliable production for decades.

Field-Proven Performance: Case Studies from Around the World

- On the Cygnus gas field in the UK, halite deposits threatened to choke near-horizontal sand-face completions at depths of more than 11,000 feet. TCO’s Q-Series devices were deployed across four lower-completion nodes, each calibrated to deliver 282 litres per day. Crucially, the devices operated independently of control-line pressure, maintaining reliable, pressure-independent distribution. The installation prevented halite build-up, preserved flow, and demonstrated how calibrated multi-node injection can avert costly interventions.

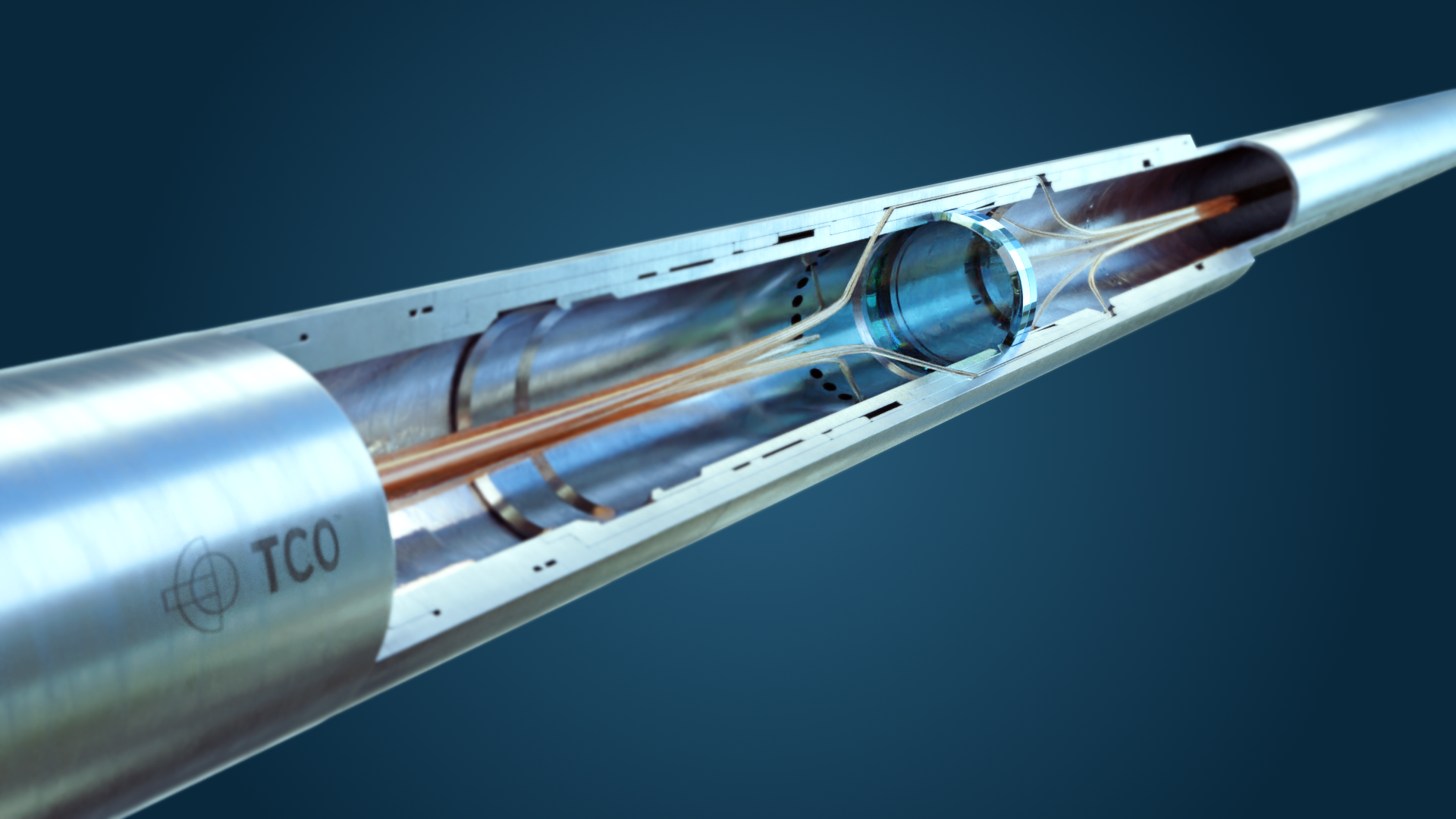

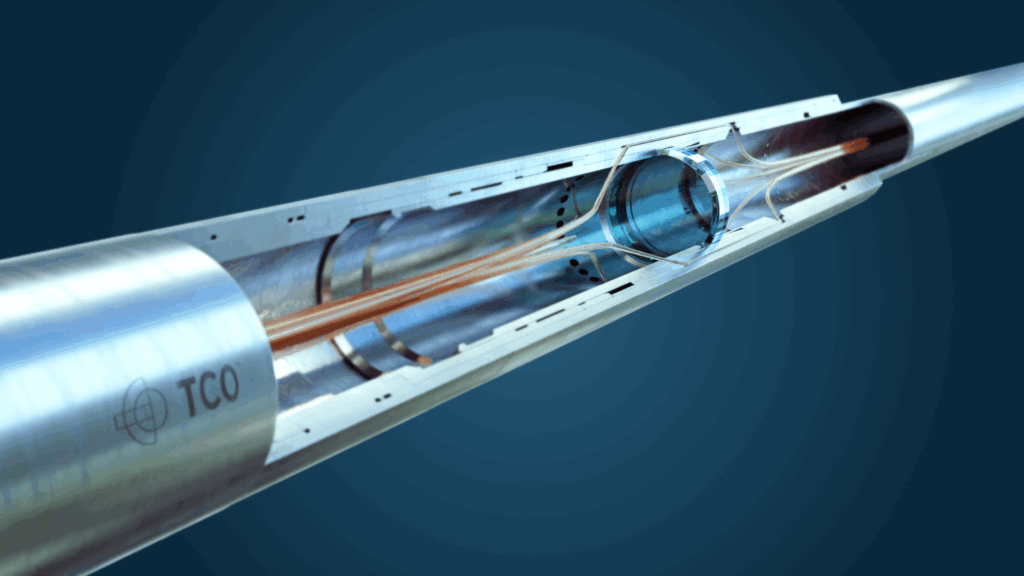

- In the Caspian Sea, an operator needed to deploy an optical fibre for distributed temperature sensing inside a fragile ¼-inch control line, in an environment of 10,000 psi pressure and temperatures near 70°C. TCO’s HN modular assembly, fitted with three catch screens and a rupture cartridge, not only enabled chemical injection but also protected the fibre from particulate damage while maintaining a dual-check barrier. A potential weak link became a robust, high-integrity completion.

- In West Africa, two projects underscored the value of adaptive valve design. In one, TCO delivered a dual mandrel system with FA back-pressure valves. The valves allowed unrestricted chemical flow at high initial reservoir pressures, automatically transitioning to regulated injection as the well depleted. The operators maintained steady delivery of xylene and anti-scale inhibitors across both upper and lower completion zones without overburdening the surface pumps. Positive performance led to further roll-out across the field.

- In another case, rapid replacement of non-conforming valves was critical. Within weeks, TCO delivered deep-set FA valves installed below gas-lift valves and downhole gauges. From first production, the system provided validated barrier protection and reliable back-pressure performance, restoring chemical injection capability without the need for recompletion. The outcome was reduced risk, lower intervention costs, and continuous flow assurance.

These cases illustrate the core argument: chemical injection, when designed into the completion, is not a reactive fix but a proactive safeguard. It prevents flow assurance issues like hydrates, scale, or wax from ever reaching crisis point. It also protects instrumentation and control lines, extending the life of monitoring systems that operators rely on. Lastly, it reduces the number of interventions by providing retrievable and retrofit options, such as straddle mandrels, that restore injection capability without pulling the string.

Lifecycle Management: Sustaining Chemical Injection for Decades

Maintenance and future-readiness are equally important to operational engineers. Beyond day-one performance, TCO’s modular chemical injection system is designed with lifecycle management in mind. For engineers tasked with long-term asset integrity, this means predictable inspection intervals, lower non-productive time, and reduced exposure to unplanned interventions. In practice, this shifts chemical injection into a sustainable asset, ensuring that treatment remains effective across decades of field life.

Embedding Chemical Injection in the Future of Well Design

Modern wells are getting deeper, hotter, more reliant on artificial lift, and more expensive to intervene in. By embedding chemical injection into the design from the start, operators can reduce uncertainty, improve predictability, and operate with confidence. TCO’s Chemical Injection System is modular, barrier-focused, and proven from the Southern North Sea to West Africa. It shows how foresight can be engineered into every completion, making chemical injection not a hidden overhead, but a guardian of modern wells.

1https://issuu.com/alaincharles/docs/ora_4_2023