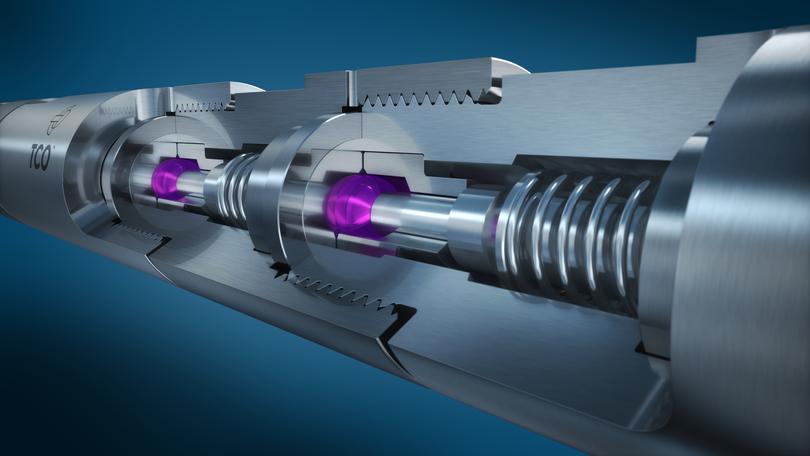

The HN represents the conventional series with a broad range of configurations, from a single compact barrier check valve to a modular dual or triple in-line ISO 14310 V0 barrier qualified check valve system. The main purpose of the HN-Series is to create the primary seal between the production tubing and the control line.

Features and Benefits

• Single/dual check valves

• Special triple check valves

• Equinor TR2385 qualified

• ISO 14310 V0 and 14998 V0 barrier qualified

• Dual check valves, completes well barrier envelope

• High temperature up to 204 °C / 400 °F (model dependent)

• High pressure up to 15,000 psi / 1034 bar (model dependent)

• Testable system integrity

Applications

• Continuous chemical injection wells

• HPHT wells